Raws li kev lag luam yooj yim hauv kev tsim kho kev lag luam thoob ntiaj teb, kev txhim kho ntawm kev lag luam foundry yog ze ze rau txoj kev loj hlob ntawm kev lag luam thoob ntiaj teb.

1. Keeb kwm ntawm lubProj

Lub tuam txhab ua lag luam high-precision casting nyob rau hauv Suav teb tsis yog tsuas yog muaj tag nrho cov txheej txheem kev txawj ntse casting ntau lawm kab los ntawm lub teb chaws Yelemees thiab Nyiv, tab sis kuj muaj peev xwm tsim txhua xyoo ntawm 75,000 tons ntawm high-precision castings.Cov txheej txheem casting thiab kev ua tau zoo kuj tau mus txog qib siab thoob ntiaj teb, thiab koom nrog thiab tsim ntau lub teb chaws (kev lag luam) cov qauv.

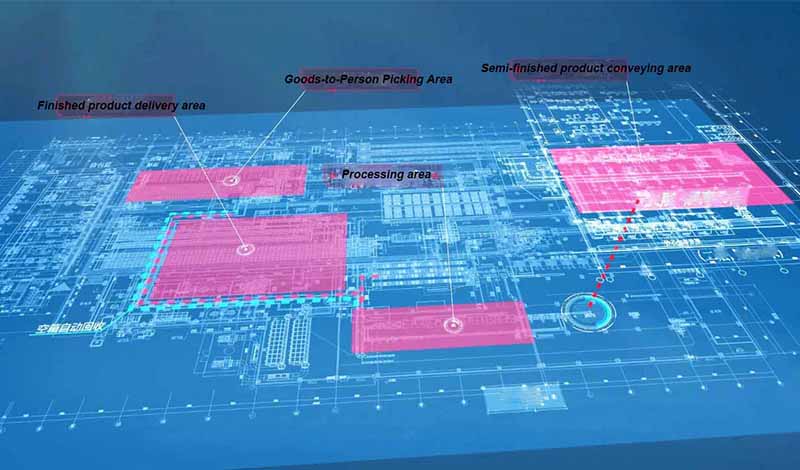

2. Tsim lub Hoobkas ntse nrog ROBOTECH

- Multi shuttle system

- Lub thawvconveying system

- Electrical tswj system

- warehouse tswj thiab teem caij system WMS & WCS

Raws li peb txhua tus paub, cov txheej txheem xuab zeb core casting muaj ntau haiv neeg thiab cov txheej txheem sib txuas zoo.Tus yuam sij rau kev ua tiav ntawm qhov project yog los xyuas kom meej cov kev xav tau ntawm cov txheej txheem pace thiab kev ruaj ntseg thiab kev ntseeg siab ntawm cov khoom siv.Tag nrho lub Hoobkas ntse yog tsim los ntawm plaub lub subsystems:ntau shuttle system, boxconveying system, hluav taws xob tswj qhov system, kev tswj cov khoom lag luamthiabscheduling system WMS & WCS.

- Covob txheej txheejlub thawvconveying systempaub qhov tsis siv neeg conveying ntawm cov ntaub ntawv nyob rau hauv tag nrho cov txheej txheem ntawm cov tub ntxhais ua-core, core sib dhos, dip-txheej, ziab, core teeb, thiab tsim cov khoom-rau-tus neeg rau tag nrho cov kab ntau lawm.

- Nws yog tailored-tsim rau casting ntau lawm, tag nrho xav txog ntau yam txawv txav nyob rau hauv cov txheej txheem ntau lawm (kab hloov reflow, txawv txav, overtime back-baking).

Lub conveying kab ntawm noob txheej txheej conveying systemyog lub voj kaw, thiab cov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob.Nws ua tauzoo pab ntau lawmthaum paub txog cov lus nug tiag tiag ntawm nws cov kab ntau lawm.Tsis tas li ntawd xwb, ROBOTECH kuj tseem siv ntau lub kaw lus nrog kev ntseeg siab rau kev khaws cia.Nrog lub lifter kawg ntawm txoj kab, qhov ntws ntawm ib txoj kab khiav yog300 boxes / teev, thiab ntau dua8,000 lub thawv ntawm cov xuab zeb corestuaj yeem khaws cia rau hauv aQhov chaw 600-square-meter.

3. Smart Factory Project Highlights

1).Automated casting

Txhaum lub lag luam lub tswv yim ntawm cov pa casting ib leeg hauv av ntau lawm kab, nws tau tsim ib tug tshiabav-rau-huab cua automated Hoobkas ntau lawm systemkev thauj mus los hauv av, kev ncig hauv av thiab kev thauj mus los ntau dua.Ua kom siv tag nrho ntawm qhov chaw txwv thiab txhim kho kev tsim khoom.

2).Cov cuab yeej siv siab heev

Qhov projecttxuag 2/3 ntawm kev ua haujlwm ntawm cov kab ntau lawmntawm tib lub teev, thiab tib lub sijhawmtxhim kho cov kev ua tau zoo ntawm 25%, thiab tauua tiav txhua xyoo tso zis ntawm 35,000 tons ntawm castings.

3).Tag nrho cov txheej txheem ntawm WCS / WMS kev tswj hwm thiab tswj

Lub foundry ntse Hoobkas realizes lubintensification ntawm Hoobkas av, txawj ntse ntau lawm, thiab recycling ntawm pov tseg.Txais high-end core intelligent manufacturing khoom thiab cov ntaub ntawv software system los tsimhigh-precision casting kev sib koom tes tsim, hloov tau yooj yim customization, ntse tsim kev daws teeb meem, coj kev lag luam los txhim kho qib kev tsim khoom.

NanJing Inform Storage Equipment (Group) Co., Ltd

Xov tooj: +86 13851666948

Chaw nyob: No. 470, Yinhua Street, Jiangning District, Nanjing Ctiy, Suav teb 211102

Lub Vev Xaib:www.informrack.com

Email:kevin@informrack.com

Post lub sij hawm: Apr-02-2022