Iqembu le-Kyocerayasungulwa ngo-1959 nguKazuo Inamori, omunye "Wabangcwele Abane Bebhizinisi" eJapane.Ekuqaleni kokusungulwa kwayo, yayizibandakanya kakhulu emikhiqizweni ye-ceramic kanye nemikhiqizo yobuchwepheshe obuphezulu.Ngo-2002, ngemva kokukhula okuqhubekayo, i-Kyocera Group yaba enye yezinkampani ze-Fortune 500, enezindawo zamabhizinisi emhlabeni wonke ezihlanganisa izinto ezingavuthiwe, izingxenye, amathuluzi, imishini, kanye nezinsizakalo, amanethiwekhi, neminye imikhakha.Ngo-2019, iKyocera Group ihlela ukwakha imboni yamabhethri e-Osaka, entshonalanga neJapan, iqondiseimakethe ye-solar + yokugcina amandla.

Kuyaqondakala ukuthi i-Kyocera Group ilindele lukhulu kule phrojekthi futhi ihlela ukusekela ukuthuthukiswa kwebhizinisi lebhethri lokugcinwa kwamandla e-Kyocera eminyakeni emi-5 ezayo ngemva kokuqedwa kwephrojekthi.I-ROBOTECH yaklama futhi yakha uhlelo oluzenzakalelayo lwe-warehouse yayo, ifinyelela ngokuzenzakalelayo, i-digitization, nokuphathwa okuhlakaniphile kwayo yonke inqubo yokukhiqiza nokugcinwa, ukusiza ukuxazulula amaphuzu ezinhlungu njengezindleko eziphezulu, ukusebenza kahle okuphansi, izinqubo eziningi, nokuphathwa kwezinto eziyinkimbinkimbi, ukunciphisa izindleko. kanye nokwandisa ukusebenza kahle, kanye nokuzuza ukuxhumana okusebenzayo nokusebenzisana phakathi kwemigqa yokukhiqiza kanye nemishini.

Ukuze kuthuthukiswe izinga lokusetshenziswa kwendawo yebhethri, i-ROBOTECH isebenzise ngokugcwele ngaphezu kwalokho4m yesikhala esiqondilefuthi udale indawo yokugcina impahla ezenzakalelayo enezindawo ezimbili zokugcina:indawo yokushaja neyokukhipha ibhethrifuthiIgumbi lebhethri lokushisa indawo yokugugangokusekelwe ezicini zekhwalithi yomkhiqizo, okuhlanganisa amasethi amabili wesistimu ye-stacker crane.

- Indawo yokushaja nokukhipha

- Isethi yesistimu ye-stacker crane

- 5000 izindawo zezimpahla

1. Indawo yokushaja nokukhipha

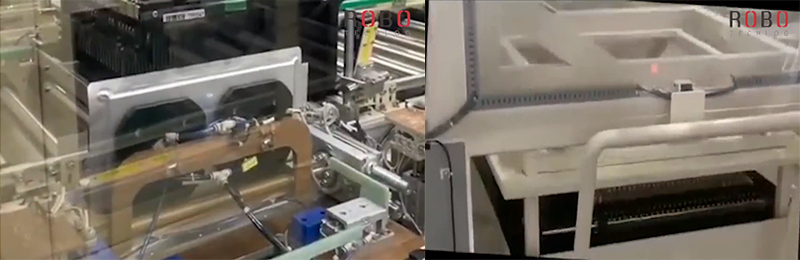

Isethi yeisitakii-craneuhleloKuhlelelwe ukushaja nokukhipha ukuhlelwa kwesifunda ukuze kutholakale isitoreji esiphephile nesonga amandla ngaphezu kwalokho5000 izindawo zezimpahla.Ukuphendula izidingo eziphezulu zokuphepha zale phrojekthi, i-ROBOTECHuhlelo lwe-stacker craneifakwe izithombe ze-infrared thermal kanye namadivayisi okuqapha, angakwazi ukubona okungavamile ngesikhathi futhi aqinisekise ukusebenza okuphephile kwayo yonke inqubo.Futhi isignali ikhiyiwe nesisetshenziswa ngasinye sokushaja nesikhiphayo ngomshini wokudlulisa amehlo (8bit).Uma i-crane yesitaki yenza umsebenzi "wokukhipha" noma "wokufohla", isicelo somsebenzi sithunyelwa ngokuxhumana optical endaweni ehambisanayo yedivayisi yokushaja.Isenzo singathathwa kuphela ngemva kokugunyazwa kwesignali yedivayisi yokushaja ethi KULUNGILE.

-Izinga lokushisa elivamile lokuguga indawo

- Isethi eyodwa yesitakii-craneuhlelo

-400 izindawo zokugcina

-Mumthamo omkhulu we-100KG

2. Indawo yokuguga yokushisa evamile

Isethi eyodwa yesitakii-craneuhleloihlelelwe ilokushisa evamile ukuguga ukuhlela kwesifunda, okuhlanganisa okungaphezu kwalokho400 izindawo zokugcina, esetshenziselwa kakhulu ukugcinwa kwesikhashana kwamabhethri kunqubo evamile yokuguga kwezinga lokushisa, ene-umthamo omkhulu we-100KG.

Ngenxa yokuzwela okwedlulele kwezinto zebhethri ezintweni ezifana nomthofu, i-zinc, nethusi, ukuze kugwenywe izinto zensimbi zangaphandle kanye nothuli oluthinta ukuqina komkhiqizo, i-ROBOTECH.kwenziwe ngezifisoiphrojekthi esekelwe ekukhethweni kwemishini ye-stacker crane.Idivayisi yokuhamba isebenzisa amasondo anenjoloba anamasondo, izingxenye zensimbi zifafazwa nge-electrostatic, futhi izingxenye ze-aluminium zithola ukwelashwa kwe-anodizing ukunciphisa ukukhiqizwa kwezinto zensimbi zangaphandle.Futhi izicishamlilo nemishini yezikhali ifakiwe ukuze i-stacker crane ihlangabezane nezimfuneko zefekthri zokumelana nezinga lokushisa eliphezulu, ukungabi naluthuli, ukuvimbela umlilo nokuqhuma.

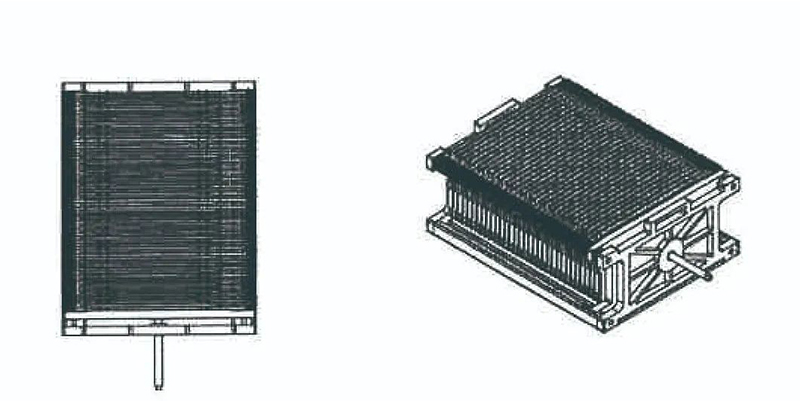

Kuhle ukusho ukuthi ekukhiqizeni amabhethri, ukuze enze ukusebenza kwawo kuzinze,zidinga ukufakwa ocingweni olunomsebenzi wokucindezela ukuze kuphumule izinga lokushisa legumbi ngemva kokwakhiwa futhi libe ngaphansi kokuphumula okuphezulu kwezinga lokushisa.Ngakho-ke, i-ROBOTECH isebenzisa ngokuqondileamathreyi okucindezela kwebhethrinjengabathwali besitoreji sokugcina.Lolu hlobo lwethreyi yokucindezela kwebhethri lunezinzuzo ezingenazo ubuchwepheshe obukhona, njengesakhiwo esilula, ukuqaliswa okulula, ukusebenza kahle kokukhiqiza okuphezulu, ukusebenza kwendawo encane, izindleko eziphansi zokuqalisa, kanye nokuqaliswa okulula kokukhiqiza okuzenzakalelayo.Kweindawo yokugcina yokushaja nokukhipha, lungisa ithreyi lokucindezela libe ngu-aisimo esicindezelwe;Kweindawo yokugcina ukushisa kwegumbi lokuguga, lungisa ithreyi yokucindezela ku-isimo esixegayo.

Umdwebo wokucaciswa kwethreyi: L865 * W540 * H290mm (isimo esixekethile)

Umdwebo wokucaciswa kwethreyi: L737 * W540 * H290mm (isimo esicindezelwe)

Umdwebo wokucaciswa kwethreyi: L737 * W540 * H290mm (isimo esicindezelwe)

Ukuphothulwa kwephrojekthi kuhlangabezana nezidingo zesevisi ye-Kyocera Group esebenza kahle, ephephile futhi enokwethenjelwa emkhakheni webhizinisi lamabhethri okugcina amandla.Ngokusekelwa isistimu yokugcina izinto ehlakaniphile ye-ROBOTECH, ingaqinisekisa kakhulu izinga lesivuno sokugcinwa kwebhethri.Kusheshiswe i-automation, intelligence, kanye nentuthuko eqhubekayo ye-Kyocera Group emakethe entsha yamandla.

I-NanJing Inform Storage Equipment (Iqembu) Co., Ltd

Umakhalekhukhwini: +8613636391926 / +86 13851666948

Ikheli: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Iwebhusayithi:www.informrack.com

I-imeyili:lhm@informrack.com

Isikhathi sokuthumela: Apr-21-2023