Factory making Warehouse Racking - AS/RS Racking – INFORM

Factory making Warehouse Racking - AS/RS Racking – INFORM Detail:

Racking Components

Product Analysis

| Racking type: | AS/RS (Automated Storage and Retrieval System) | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 1000-3000kg/pallet |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 75mm | Place of origin | Nanjing, China |

| Application: | industrial production, logistics, commodity manufacturing , military applications industries | ||

① High space Utilization

The space utilization of AS/RS is 2-5 times than common storage. The racking can be designed as single-depth or double-depth to improve storage capacity, also compatible with any size pallet.

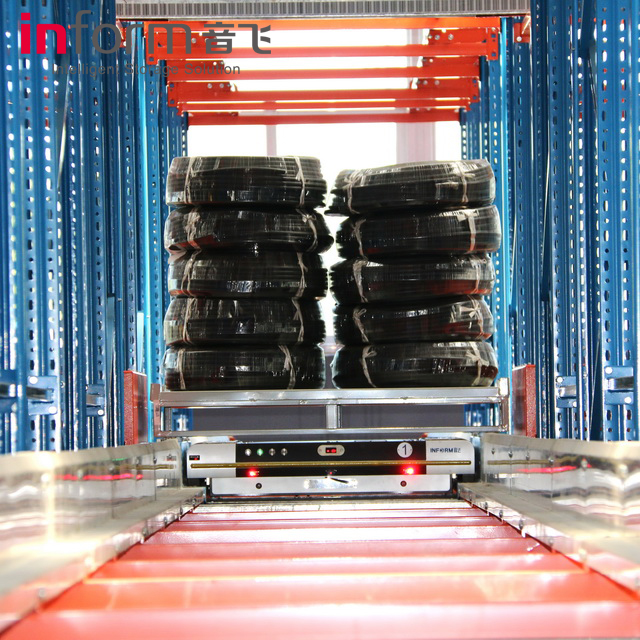

② Improving efficiency of storage and picking

AS/RS is dynamic storage and advanced logistics system, improving production management level. Compared with static racking system, the storage and picking efficiency is much improved.

③ Labor-saving operation

The pallet moving is handled by equipment, and controlled by software system. So it requires minimum labor and allows to operate unattended around the clock.

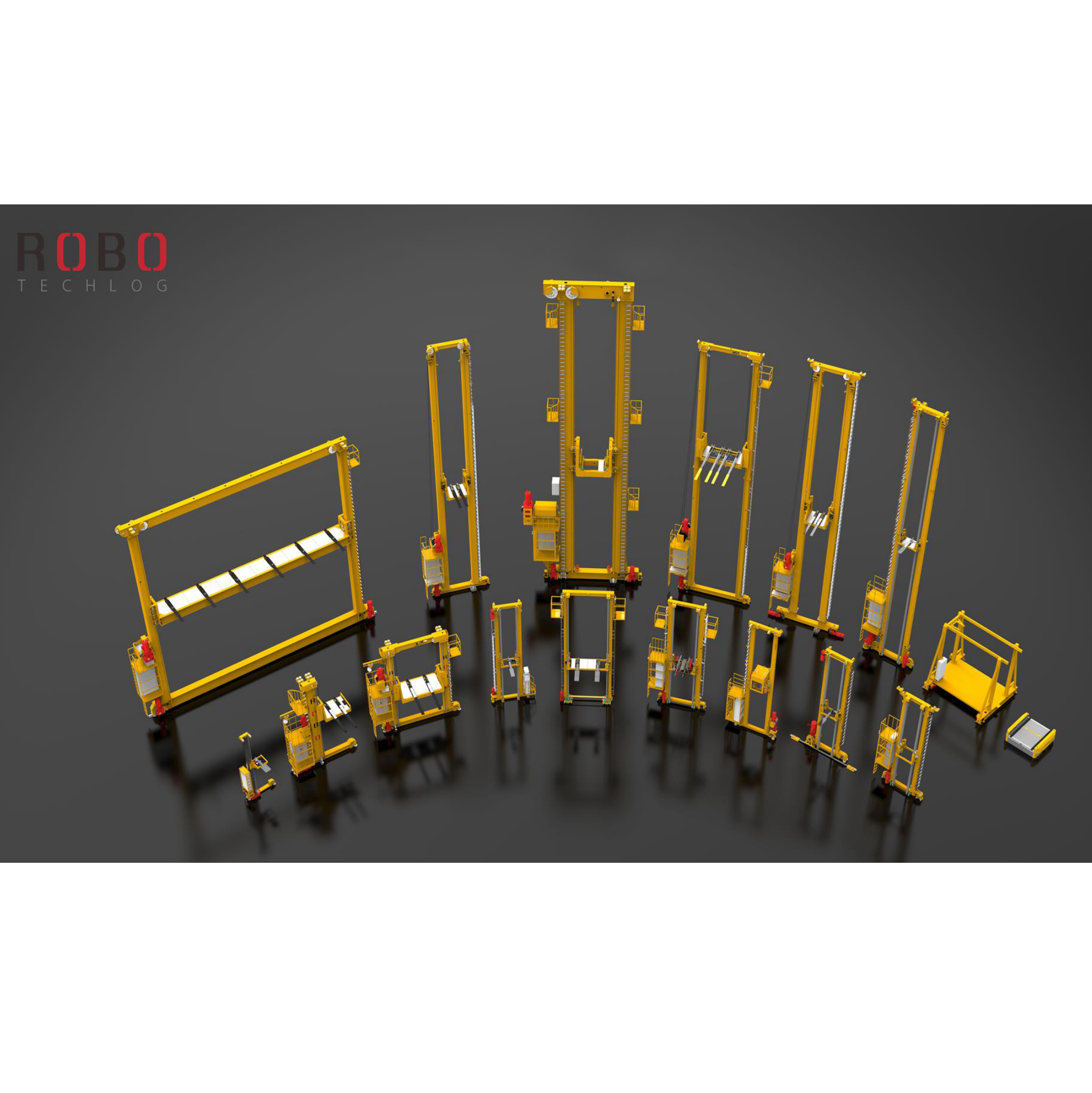

④Mini Load AS/RS

In addition to regular pallet storage, there is the other AS/RS racking type, suitable for carton/box/bin storage, called Mini Load AS/RS. Similar as AS/RS, mini load is a combination of shelving, equipments and software system.

⑤ High adaptability with other automated storage robots

AS/RS is able to work with other automated storage robots, like shuttle car, shuttle mover, four way shuttle and so on, to meet diversified storage requirement and increase efficiency.

Project cases

Industry: Paper / Pallet Positions: around 60,000 / Height: 24m

Industry: Soy Sauce Pallet Positions: around 31,000 Height: 32m

Industry: Industry: Ceramics Pallet Positions: around 52,000 Height: 26m

Miniload ASRS racking

Industry: Garments

Carton Positions: 30,000

Height: 9m

Why choose us?

Product detail pictures:

Related Product Guide:

Bear "Customer first, Excellent first" in mind, we operate closely with our customers and supply them with efficient and expert services for Factory making Warehouse Racking - AS/RS Racking – INFORM, The product will supply to all over the world, such as: Luxemburg, Denver, Rio de Janeiro, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.