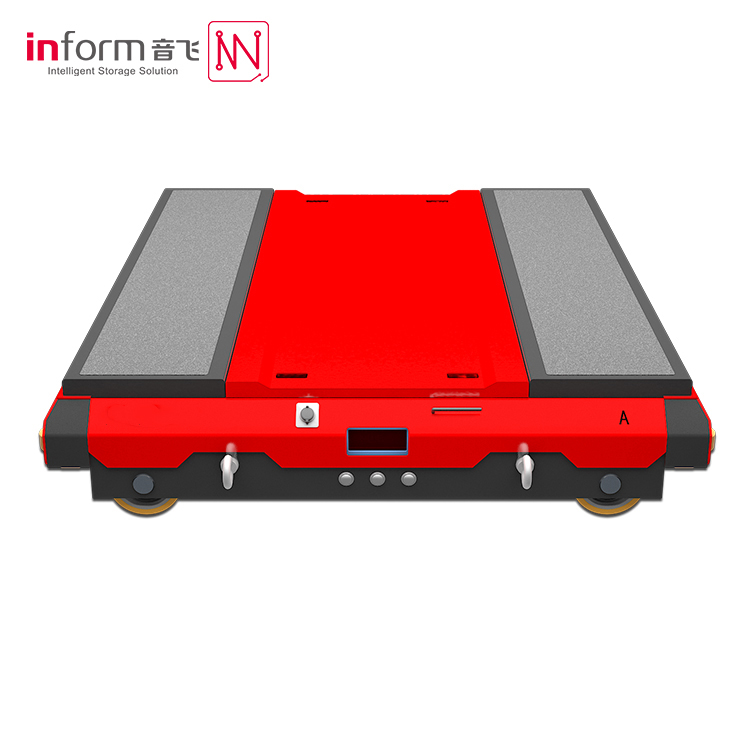

Shuttle Mover System

Introduction

Different from AS/RS, shuttle mover system is an innovative fully automated intensive warehouse, which realizes greater utilization of warehouse space and can meet greater efficiency requirements of inbound and outbound.

Main working principle:

1. Inbound: After WMS receives the information of inbound goods, it allocates cargo space based on the goods characteristics, and generates inbound instructions. WCS dispatches related equipment to automatically deliver goods to the designated location;

2. Outbound: After WMS receives the information of outbound goods; it generates outbound instructions according to cargo positions. WCS dispatches related equipment to automatically send goods to the outbound end.

Operation type:

Freely loading and unloading by taking sub-lane as storage unit, and main-lane as transport path; according to lanes layout, it can be divided into: two-side layout and middle layout.

□ Shuttle mover and rails are arranged on both sides of racking:

· Radio shuttle mode: first in first out (FIFO);

· Inbound and outbound methods: single-sided inbound and outbound;

□ Shuttle mover and rails are arranged in the middle of racking:

· Radio shuttle mode: first in last out (FILO);

· Inbound and outbound methods: inbound and outbound on one side

System advantages:

1. The perfect combination of intensive storage and automation system;

2. Fully automated storage of bulk pallets;

3. The semi-automatic raido shuttle rack can be systematically upgraded, to be interconnected with production and logistics system to achieve seamless connection.

4. Low requirements for warehouse building pattern and floor height inside the warehouse;

5. The warehouse layout is flexible, with multiple floors and regional layouts to realize fully automated storage;

Applicable Industry: cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

Customer Case

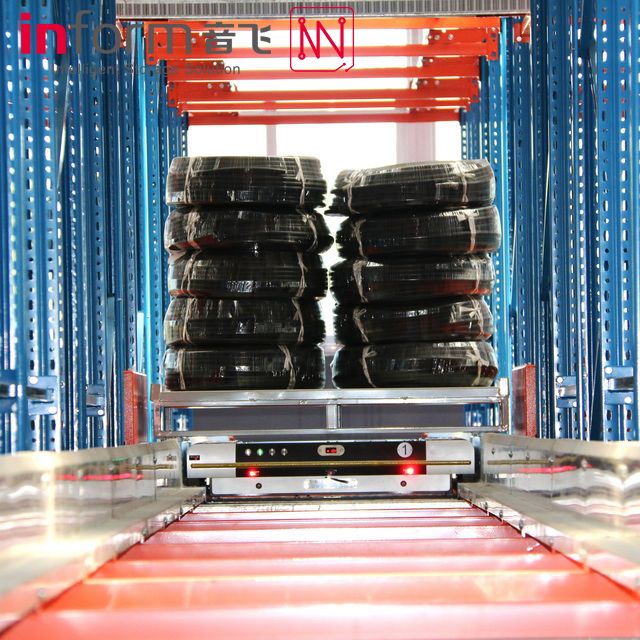

Recently, NANJING INFORM STORAGE EQUIPMENT (GROUP) CO.,LTD and Inner Mongolia Chengxin Yong'an Chemical Co., Ltd. signed a cooperation agreement on the design, manufacture, installation and commissioning of an automated warehouse system. The project adopts shuttle mover system solution, which is mainly composed of drive in racking, radio shuttle, shuttle mover, reciprocating elevators, layer changing elevators, conveyor lines, and software.

Inner Mongolia Chengxin Yong'an Chemical Co., Ltd. was established in November 2012 with a registered capital of 100 million RMB. It is a high-tech enterprise engaged in the production, operation and research and development of downstream fine chemical products of natural gas. The company is located at the northern end of Lantai Road, Alxa Economic Development Zone, Alxa League, Inner Mongolia, and currently employs 200 people.

The company has domestic and foreign advanced production equipment, inspection and testing equipment, high-quality management, production, inspection personnel and mature production technology. Product quality has reached the international advanced level.

Project Overview

In this project, pallets are stored by shuttle mover system. Total warehouse area is 3000 square meters. The plan has 6 levels of racking and 6204 cargo spaces, by 1 shuttle mover lane, 4 sets of shuttle mover + radio shuttle, 3 sets of pallet elevators, 1 set of shuttle mover elevator, and conveying equipment, to realize the automated inbound and outbound. The pallet labels are all barcoded for information management, and external dimension detection and weighing are provided before storage to ensure safe inbound.

System operation capacity: 5 pallets/hour for inbound (24 hours), and 75 pallets/hour for outbound (8 hours).

Project Benefits

1. The stored goods are cyanide. It's an unmanned warehouse, requiring zero or very low failures of storage equipment to prevent people from entering and leaving the warehouse to overhaul the equipment and contact with hazardous chemicals;

2. The warehouse working hours are 24H. It is connected to the production line, requiring zero or very low failures of storage equipment to avoid affecting the production line;

3. Dense storage makes full use of warehouse space.

4. Warehouse inbound and outbound position are flexible. The project warehouse is long strip, inbound and outbound positions are respectively in the middle of the warehouse. By adopting shuttle mover system, it can meet the customer's requirements for inbound and outbound position with the least line , which can't be realized by conventional AS/RS.

Through WMS/WCS, fully automated operation of radio shuttle, shuttle mover, elevator, conveyor and other equipment is realized, forklift channels and auxiliary spaces are eliminated, greatly improving the density of materials, saving the time for forklifts to access materials, reducing working hours of operators, at the same time meeting the requirements of customers for high-density storage and high-efficiency access to materials.

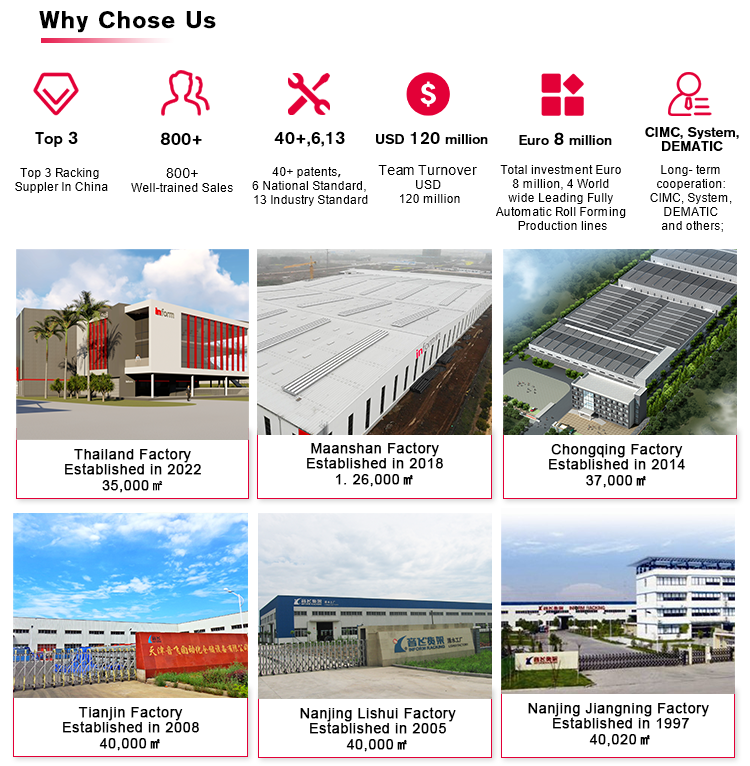

Why Choose Us

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed enterprise, specialized in the logistic storage solution field since 1997( 27 years of experience).

2. Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3. Inform owns 6 factories, with over 1500 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.