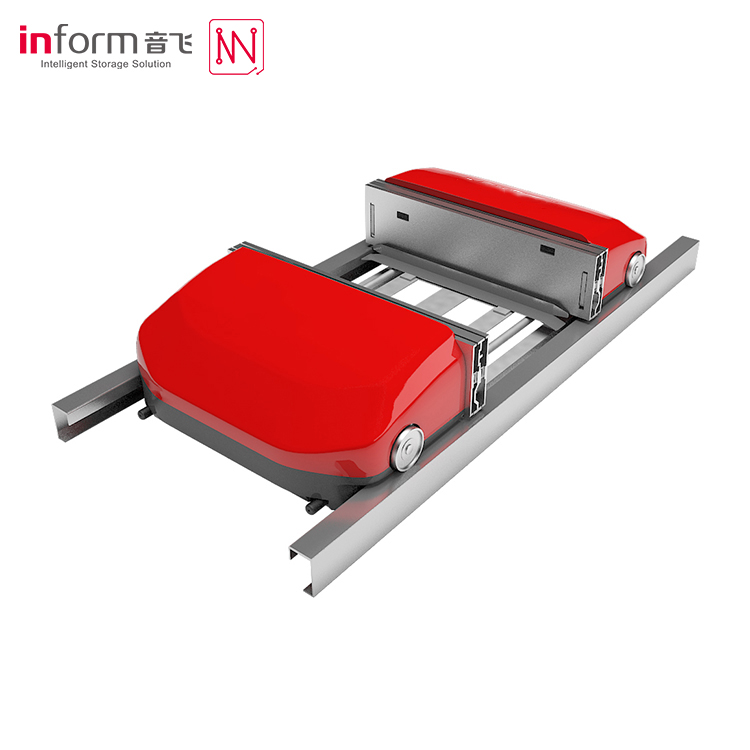

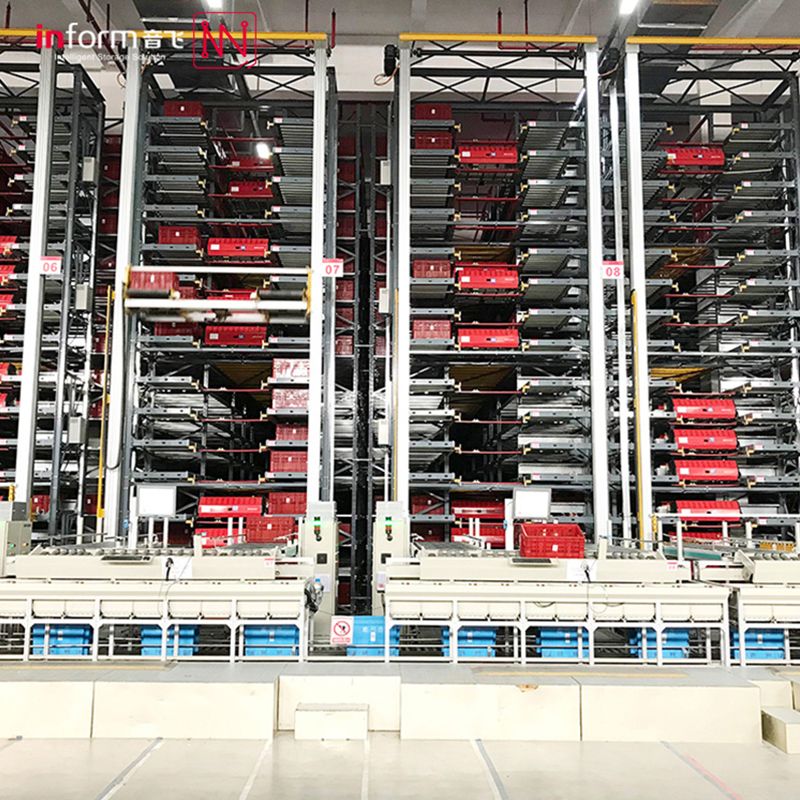

Multi Shuttle

Overview

Product Analysis

①Functions

| 1 | Automatic single inbound | Accepting instruction from host computer, automatically conveys box on inbound buffer area to specified storage position. |

| 2 | Automatic single outbound | Accepting instruction from host computer, conveys box on specified position to outbound end. |

| 3 | Automatic shifting | Accepting instruction from host computer, conveys box from one specified position to another. |

| 4 | Charging online | Multi-level power threshold control, self-judging and self-charging on line. |

| 5 | Self-learning function | Automatically measure, identify data of racking and pallet, and enter parameters independently |

| 6 | Remote function | It is capable of updating and downloading program remotely (In Wi-Fi Network) |

| 7 | System monitoring | Monitors system data in real time and alarm raised in sound and light in abnormal status. |

| 8 | Heartbeat check | Communicate to host computer control system in real time by heartbeat check, monitoring online status |

| 9 | Emergency Stop | Emergency signal sent remotely when emergency, and shuttle stops instantly until emergency lifted.It is capable of guaranteeing device or goods stop safely in maximal deceleration when it executes this instruction. |

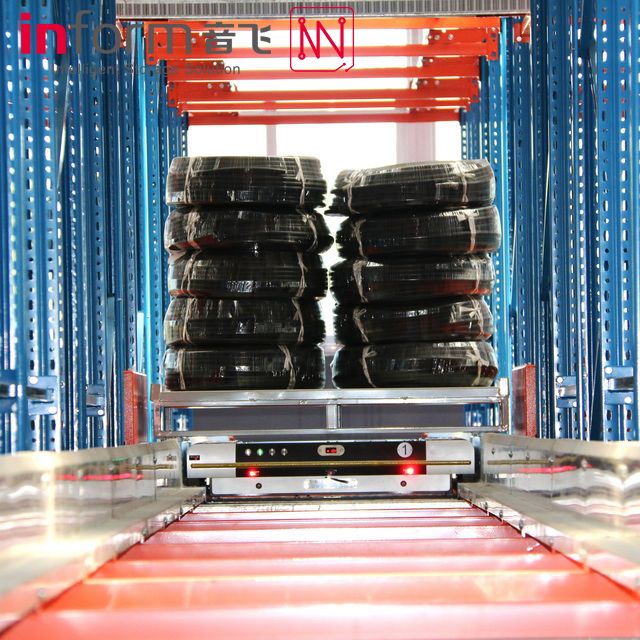

②What kind of goods are suitable for Four-way Multi Shuttle Storage System ?

Goods package type: Bins, Cartons, totes and etc

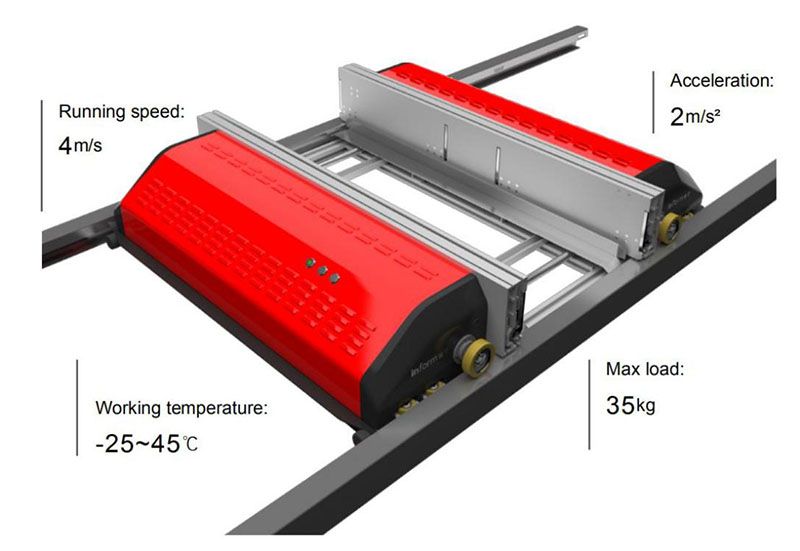

Goods dimension(mm): Width:200-600mm; Depth:200-800mm; Height:100-400mm

Goods weight: <=35kg

Operation height <=15m

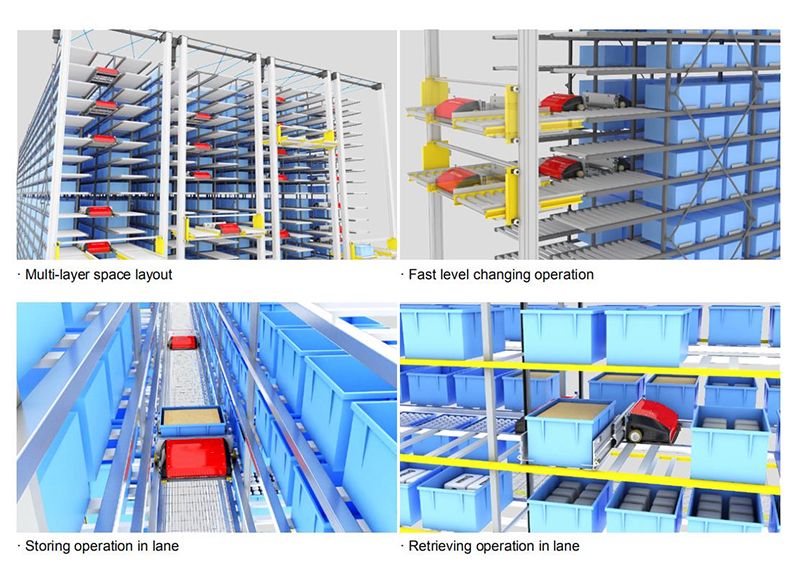

③Features

Lightweight aluminum structure.

Single or double deep storage.

Quick level changing operation.

Picking, replenishing, temporary storage, goods to person.

Low-voltage power supply, consume less energy.

Processing capability 3-4 times than AS/RS.

Applicable Industry: cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

④Design, Test &Warranty

Design

Free design could be provided with the following information.

Warehouse storage area Length____mm x Width____mm x Clear height___mm.

Warehouse’s door position for loading and unloading goods.

Bins,cartons Length____mm x Width____mm x Height___mm x Weight_____kg.

Warehouse Temperature_____Degrees Celsius

Inbound and outbound efficiency: Quantity of bins or cartons per hour_____.

Test

Multi shuttle will be tested before delivery. Engineer will test the whole system on-site or online.

Warranty

Warranty is one year. Fast response within 24 hours for overseas customer. Firstly test online and adjust ,if couldn’t repair online , engineer will go and solve the problems on site. Free spare parts will be supplied during the warranty time.

Project cases

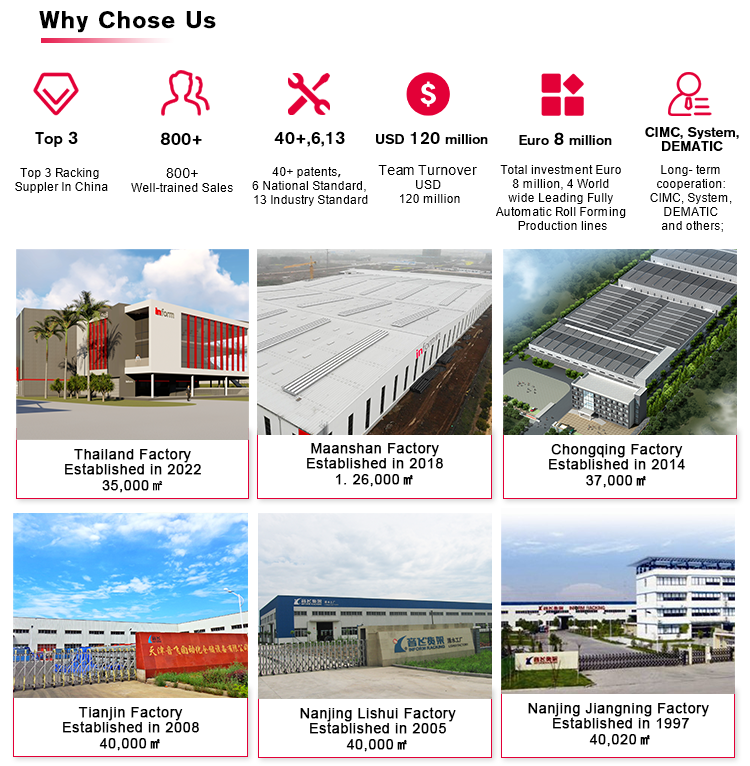

Why Choose Us

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed enterprise, specialized in the logistic storage solution field since 1997( 27 years of experience).

2. Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3. Inform owns 6 factories, with over 1500 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.