Shuttle System

-

Four Way Radio Shuttle

1.Four way radio shuttle is an intelligent equipment which is applied to pallet handling.

2. Compact racking storage system in shuttle style could maximize the space utilization to store in high density, decrease cost and improve flexibility

3. Four way shuttle system, as a kind of fully automatic storage solution, realizes unmanned batch operation of palletized goods in 24 hours, suited to low flow and high density storage as well as high flow and high density storage. It is widely applied in different industries, such as garment, food and beverage, automobile, cold chain, tobacco, electricity and so on.

-

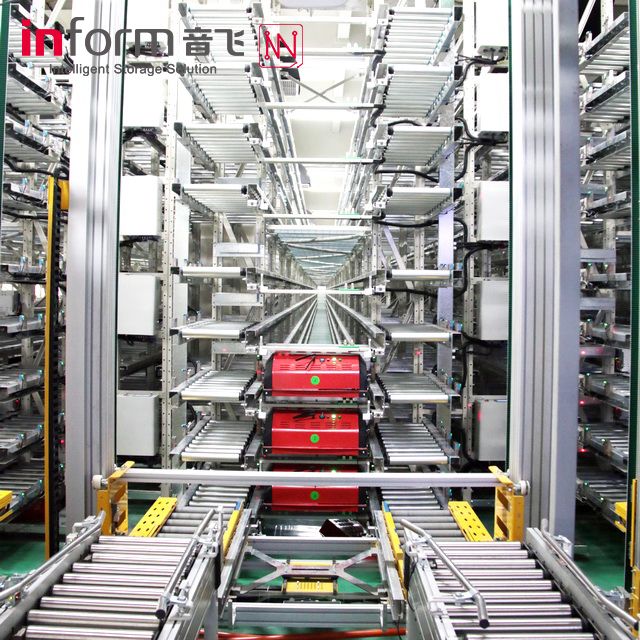

Multi Shuttle

1.Multi Shuttle system consists of multi-tier racking, shuttle, conveyor in front of racking, lifter, pick-up station and software. Each level of the conveyor cooperates with shuttle and one shuttle could be allocated in one only or more levels. The lift at the end of aisle delivers the goods to conveyor.

2. Multi Shuttle, as an efficient storage equipment for bins and cartons storage, is the best choice for order picking and replenishment of small goods, also can be used for temporary storage to support production line operations. It allows fast and accurate sort and pick, saving space and in flexibility.

3. Goods are delivered to picking station through conveying equipment by quick and accurate sorting, to ensure high working efficiency. Multi Shuttle system is especially suitable for E-commerce industry and Automobile industry.

-

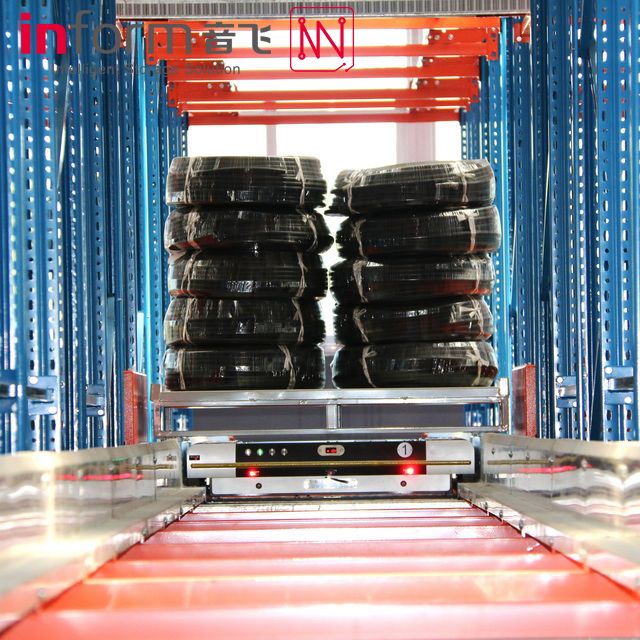

Radio Shuttle

1. Radio Shuttle Rack System is an semi-automatic storage solution for industrial warehouse, using shuttle instead of forklift to store goods inside of racks. 2. As radio shuttle only retrieves the pallet at rack ends, it is suitable for less category and large batch goods, such as food, tobacco, freezer, beverage, pharmacy and etc. Generally, one lane is for only one category of goods

-

Two Way Radio Shuttle System

1. Due to the continuous increase in domestic land costs and labor costs, as well as the huge increase in e-commerce’s massive product regulations and order requirements for warehouse efficiency, two-way radio shuttle system has attracted more attention of enterprises, its application becomes more and more extensive, and the market scale is bigger and bigger

2. Two-way radio shuttle system is a major innovation in logistics equipment technology, and its core equipment is radio shuttle. With the gradual solution of key technologies such as batteries, communications, and networks, two-way radio shuttle system has been quickly applied to logistics systems. As a unique automated logistics system, it mainly solves the problems of dense storage and fast access.

-

Two Way Multi Shuttle System

The efficient and flexible combination of “two way multi shuttle + fast elevator + goods-to-person picking workstation” meets the requirements of customers for different inbound and outbound frequency. Equipped with WMS and WCS software independently developed by INFORM, it effectively optimizes the order picking sequence, and dispatches various automated equipment to achieve rapid warehousing, and can pick up to 1,000 goods per person per hour.

-

Four Way Radio Shuttle System

Four way radio shuttle system: a complete level of cargo location management (WMS) and equipment dispatching capability (WCS) can ensure the stable and efficient operation of the overall system. In order to avoid waiting for the operation of radio shuttle and elevator, a buffer conveyor line is designed between elevator and rack. Radio shuttle and elevator both transfer the pallets to the buffer conveyor line for transfer operations, thereby improving efficiency.

-

Shuttle Mover System

In recent years, shuttle mover system has developed into a flexible, easy-to-use, energy-saving and environmentally-friendly new delivery equipment in logistics industry. Through the organic combination and reasonable application of shuttle mover + radio shuttle with dense warehouses, It can better adapt to the development and changing needs of enterprises.

-

Miniload ASRS System

Miniload stacker is mainly used in AS/RS warehouse. The storage units are usually as bins, with high dynamic values, advanced and energy-saving drive technology, which enables the customer’s small parts warehouse to achieve higher flexibility.

-

ASRS+Radio Shuttle System

AS/RS + Radio shuttle system is suitable for machinery, metallurgy, chemical, aerospace, electronics, medicine, food processing, tobacco, printing, auto parts, etc, also suitable for distribution centers, large-scale logistics supply chains, airports, ports, also military material warehouses, and training rooms for logistics professionals in colleges and universities.

-

Attic Shuttle

1. Attic Shuttle System is a kind of fully-automated storage solution for bins and cartons. It could store goods quickly and accurately, occupying less storage space, requiring less space and is in more flexible style.

2. Attic shuttle, equipped with a up-and-down moveable and retractable fork, moves along the racking to realize loading and unloading at different levels.

3. The working efficiency of Attic Shuttle System is not higher than Multi Shuttle system. So it’s more suitable for the warehouse requiring not so high efficiency, in order to save cost for the users.

-

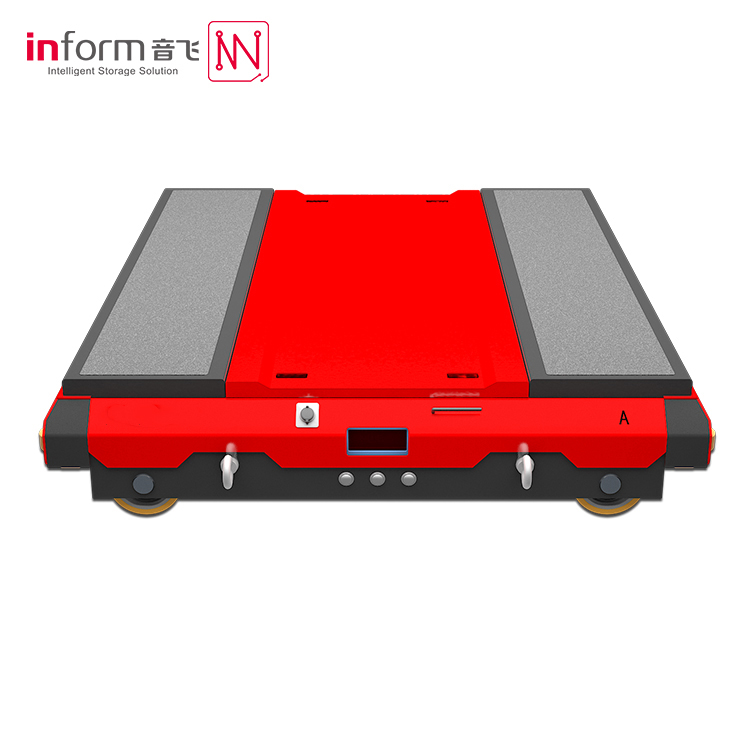

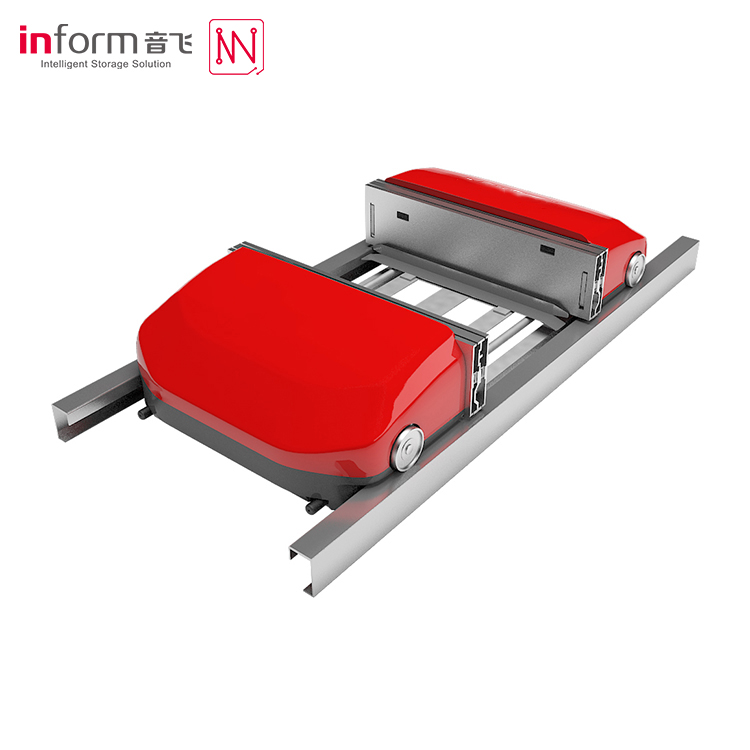

Shuttle Mover

1. Shuttle mover, working in combination with radio shuttle, is a fully automatic and high density storage system, consists of shuttle mover, radio shuttle, racking, shuttle mover lifter, pallet convey system, WCS, WMS and so on.

2. Shuttle mover system is widely used in different industries, such as garment, food and beverage, automobile, cold chain, tobacco, electricity and so on.