High Quality Automated Racking System – Heavy Load Stacker Crane Asrs – INFORM

High Quality Automated Racking System – Heavy Load Stacker Crane Asrs – INFORM Detail:

Product Analysis:

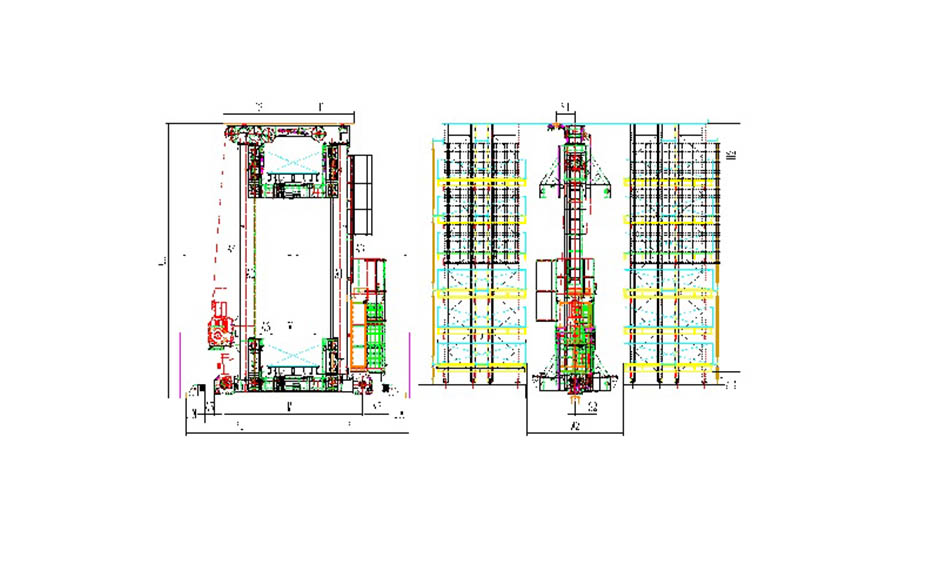

| Name | Code | Standard value (mm) (detailed data is determined according to the project situation) |

| Width | W | 400≤W≤2000 |

| Depth | D | 500≤ D≤2000 |

| Height | H | 100≤ H≤2000 |

| Total height | GH | 5000<GH≤20000 |

| Top rail end length | F1、F2 | Confirm according to the specific plan |

| Outer width of stacker crane | A1、A2 | Confirm according to the specific plan |

| Stacker crane distance from the end | A3、A4 | Confirm according to the specific plan |

| Buffer safety distance | A5 | A5 ≥ 300 (polyurethane), A5 ≥ 100 (hydraulic buffer) |

| buffer stroke | PM | PM ≥ 150 (polyurethane), specific calculation (hydraulic buffer) |

| Cargo platform safety distance | A6 | ≥165 |

| Rail end length | B1、B2 | Confirm according to the specific plan |

| Stacker crane wheel distance | M | M=W+2800(W ≥ 1300), M=4100(W < 1300) |

| Ground rail offset | S1 | Confirm according to the specific plan |

| Top rail offset | S2 | Confirm according to the specific plan |

| Pickup Itinerary | S3 | ≤3000 |

| Bumper width | W1 | 450 |

| Aisle width | W2 | D+200(D≥1300), 1500(D<1300) |

| First floor height | H1 | Single deep H1 ≥800, double deep H1 ≥900 |

| Top level height | H2 | H2 ≥ H+675(H ≥ 1130), H2 ≥ 1800(H < 1130) |

Advantages:

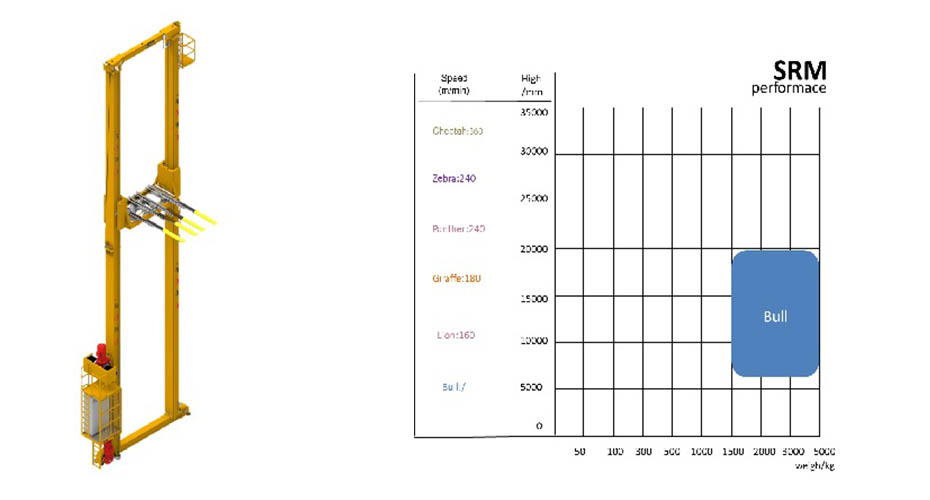

The Bull series stacker crane is ideal for handling heavy loads up to 15,000kg and installation heights up to 25m.

• Installation height up to 25 meters.

• There is an inspection and maintenance platform.

• Shorter end distance for flexible installation.

• Variable frequency drive motor (IE2), running smoothly

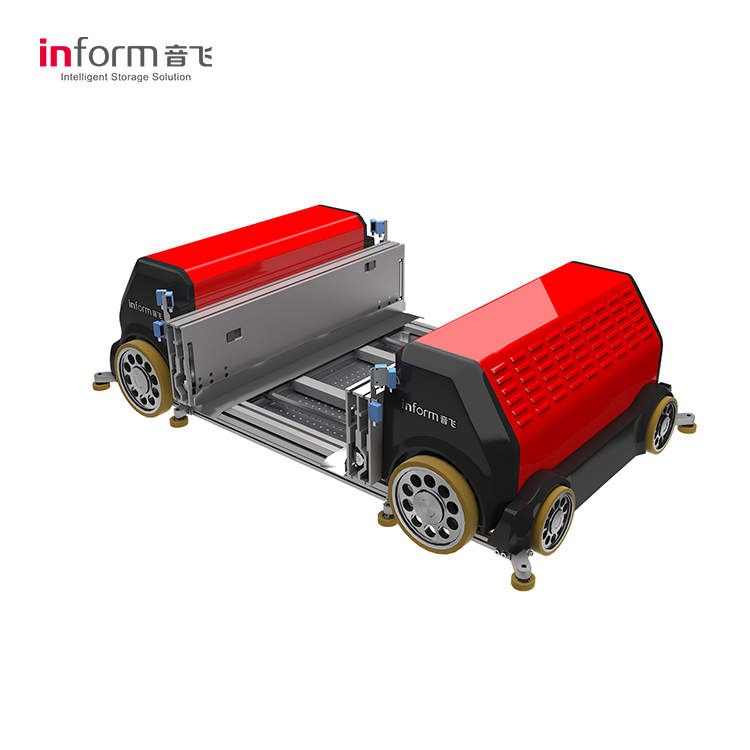

• Fork units can be customized to handle a variety of loads.

• The minimum height of the first floor: 800mm.

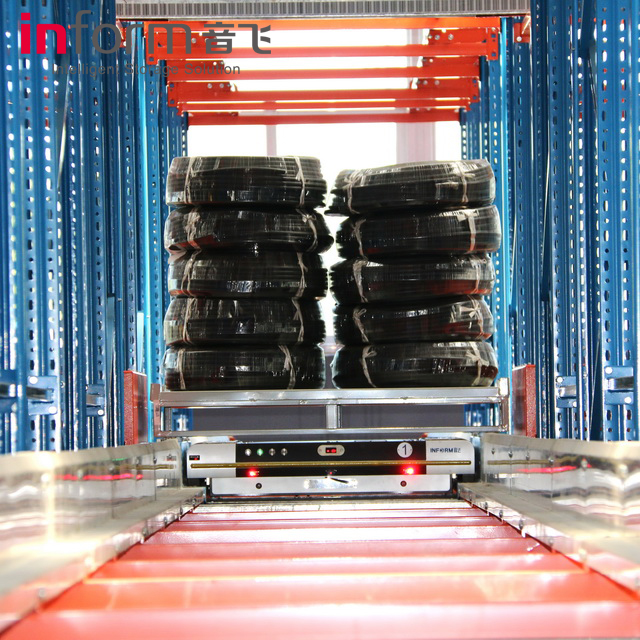

Applicable Industry: cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

Project case:

| Model Name |

TMHS-P5-5000-08 | ||||

| Bracket Shelf | Standard Shelf | ||||

| Single Deep | Double deep | Single Deep | Double deep | ||

| Maximum height limit GH | 20m | ||||

| Maximum load limit | 5000kg | ||||

| Walking speed max | 100m/min | ||||

| Walking acceleration | 0.5m/s2 | ||||

| Lifting speed(m/min) | Fully loaded | 30 | 30 | 30 | 30 |

| No load | 40 | 40 | 40 | 40 | |

| Lifting acceleration | 0.3m/s2 | ||||

| Fork speed(m/min) | Fully loaded | 30 | 30 | 30 | 30 |

| No load | 60 | 60 | 60 | 60 | |

| Fork acceleration | 0.5m/s2 | ||||

| Horizontal positioning accuracy | ±3mm | ||||

| Lifting positioning accuracy | ±3mm | ||||

| Fork positioning accuracy | ±3mm | ||||

| Stacker crane Net Weight | About14,500kg | About15,000kg | About14,500kg | About15,000kg | |

| Load depth limit D | 1000~1300(inclusive) | 1000~1300(inclusive) | 1000~1300(inclusive) | 1000~1300(inclusive) | |

| Load width limit W | W≤ 1300 (inclusive) | ||||

| Motor Specification and Parameters |

Level | AC;18.5kw(single extension)/22kw(double extension);3 ψ ;380V | |||

| Rise | AC;52kw;3 ψ ;380V | ||||

| Fork | AC;6.6kw; 3ψ;4P;380V | AC;-kw; 3ψ ;4P;380V |

AC;6.6kw; 3ψ ;4P;380V |

AC;-kw; 3ψ ;4P;380V |

|

| Power supply | Busbar (5P; including grounding) | ||||

| Power supply specifications | 3 ψ ;380V±10%;50Hz | ||||

| Power supply capacity | Single deep is about 78kw; double deep is about 81kw | ||||

| Top rail specifications | H-beam 125*125mm (The installation distance of top rail is not more than 1300mm) |

||||

| Top rail offset S2 | -600mm | ||||

| Rail Specifications | 43kg/m | ||||

| Ground rail offset S1 | 0mm | ||||

| Operating temperature | -5 ℃~40℃ | ||||

| Operating humidity | Below85%, no condensation | ||||

| Safety devices | Prevent walking derailment: laser sensor, limit switch, hydraulic buffer Prevent lifts from topping or bottoming: laser sensors, limit switch, buffers Emergency stop function: emergency stop button EMS Safety brake system: electromagnetic brake system with monitoring function Broken rope (chain), loose rope (chain) detection: sensor, clamping mechanism Cargo position detection function, fork center inspection sensor, fork torque limit protection Cargo anti-fall device: cargo shape detection sensor Ladder, safety rope or safety cage |

||||

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for High Quality Automated Racking System – Heavy Load Stacker Crane Asrs – INFORM, The product will supply to all over the world, such as: Malaysia, Ethiopia, Angola, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

We have been looking for a professional and responsible supplier, and now we find it.