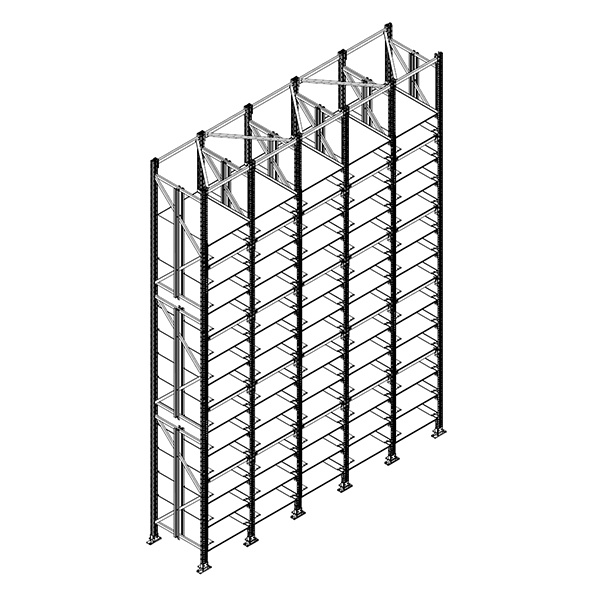

High Quality Automated Racking System – Heavy Load Stacker Crane Asrs – INFORM

High Quality Automated Racking System – Heavy Load Stacker Crane Asrs – INFORM Detail:

Product Analysis:

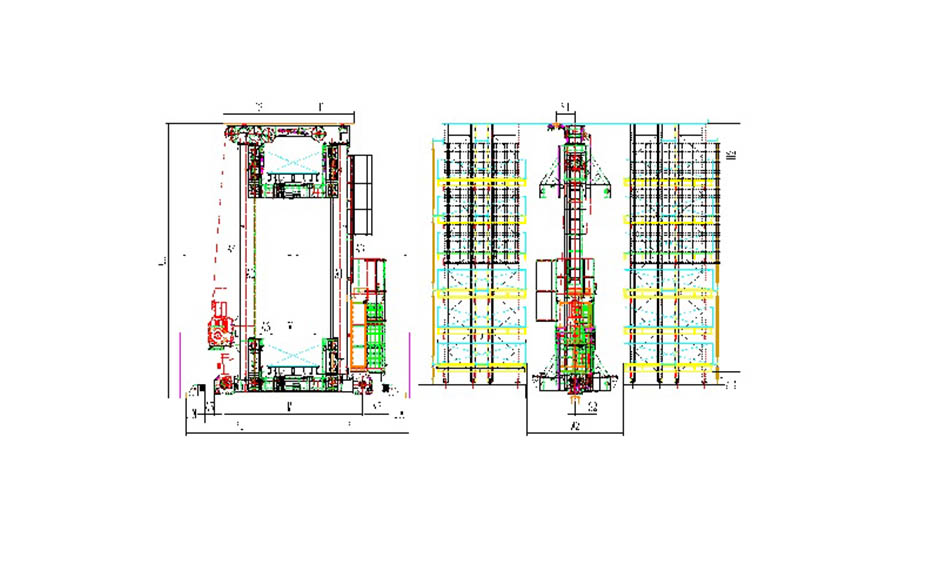

| Name | Code | Standard value (mm) (detailed data is determined according to the project situation) |

| Width | W | 400≤W≤2000 |

| Depth | D | 500≤ D≤2000 |

| Height | H | 100≤ H≤2000 |

| Total height | GH | 5000<GH≤20000 |

| Top rail end length | F1、F2 | Confirm according to the specific plan |

| Outer width of stacker crane | A1、A2 | Confirm according to the specific plan |

| Stacker crane distance from the end | A3、A4 | Confirm according to the specific plan |

| Buffer safety distance | A5 | A5 ≥ 300 (polyurethane), A5 ≥ 100 (hydraulic buffer) |

| buffer stroke | PM | PM ≥ 150 (polyurethane), specific calculation (hydraulic buffer) |

| Cargo platform safety distance | A6 | ≥165 |

| Rail end length | B1、B2 | Confirm according to the specific plan |

| Stacker crane wheel distance | M | M=W+2800(W ≥ 1300), M=4100(W < 1300) |

| Ground rail offset | S1 | Confirm according to the specific plan |

| Top rail offset | S2 | Confirm according to the specific plan |

| Pickup Itinerary | S3 | ≤3000 |

| Bumper width | W1 | 450 |

| Aisle width | W2 | D+200(D≥1300), 1500(D<1300) |

| First floor height | H1 | Single deep H1 ≥800, double deep H1 ≥900 |

| Top level height | H2 | H2 ≥ H+675(H ≥ 1130), H2 ≥ 1800(H < 1130) |

Advantages:

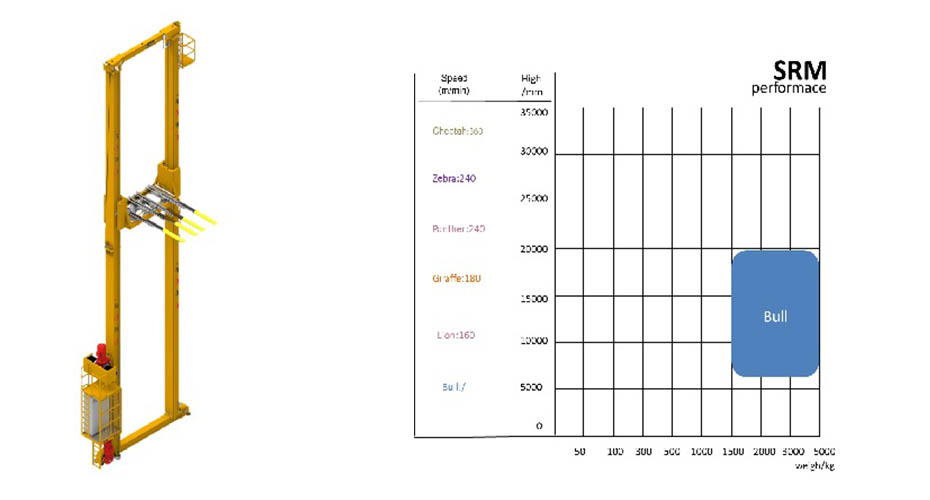

The Bull series stacker crane is ideal for handling heavy loads up to 15,000kg and installation heights up to 25m.

• Installation height up to 25 meters.

• There is an inspection and maintenance platform.

• Shorter end distance for flexible installation.

• Variable frequency drive motor (IE2), running smoothly

• Fork units can be customized to handle a variety of loads.

• The minimum height of the first floor: 800mm.

Applicable Industry: cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

Project case:

| Model Name |

TMHS-P5-5000-08 | ||||

| Bracket Shelf | Standard Shelf | ||||

| Single Deep | Double deep | Single Deep | Double deep | ||

| Maximum height limit GH | 20m | ||||

| Maximum load limit | 5000kg | ||||

| Walking speed max | 100m/min | ||||

| Walking acceleration | 0.5m/s2 | ||||

| Lifting speed(m/min) | Fully loaded | 30 | 30 | 30 | 30 |

| No load | 40 | 40 | 40 | 40 | |

| Lifting acceleration | 0.3m/s2 | ||||

| Fork speed(m/min) | Fully loaded | 30 | 30 | 30 | 30 |

| No load | 60 | 60 | 60 | 60 | |

| Fork acceleration | 0.5m/s2 | ||||

| Horizontal positioning accuracy | ±3mm | ||||

| Lifting positioning accuracy | ±3mm | ||||

| Fork positioning accuracy | ±3mm | ||||

| Stacker crane Net Weight | About14,500kg | About15,000kg | About14,500kg | About15,000kg | |

| Load depth limit D | 1000~1300(inclusive) | 1000~1300(inclusive) | 1000~1300(inclusive) | 1000~1300(inclusive) | |

| Load width limit W | W≤ 1300 (inclusive) | ||||

| Motor Specification and Parameters |

Level | AC;18.5kw(single extension)/22kw(double extension);3 ψ ;380V | |||

| Rise | AC;52kw;3 ψ ;380V | ||||

| Fork | AC;6.6kw; 3ψ;4P;380V | AC;-kw; 3ψ ;4P;380V |

AC;6.6kw; 3ψ ;4P;380V |

AC;-kw; 3ψ ;4P;380V |

|

| Power supply | Busbar (5P; including grounding) | ||||

| Power supply specifications | 3 ψ ;380V±10%;50Hz | ||||

| Power supply capacity | Single deep is about 78kw; double deep is about 81kw | ||||

| Top rail specifications | H-beam 125*125mm (The installation distance of top rail is not more than 1300mm) |

||||

| Top rail offset S2 | -600mm | ||||

| Rail Specifications | 43kg/m | ||||

| Ground rail offset S1 | 0mm | ||||

| Operating temperature | -5 ℃~40℃ | ||||

| Operating humidity | Below85%, no condensation | ||||

| Safety devices | Prevent walking derailment: laser sensor, limit switch, hydraulic buffer Prevent lifts from topping or bottoming: laser sensors, limit switch, buffers Emergency stop function: emergency stop button EMS Safety brake system: electromagnetic brake system with monitoring function Broken rope (chain), loose rope (chain) detection: sensor, clamping mechanism Cargo position detection function, fork center inspection sensor, fork torque limit protection Cargo anti-fall device: cargo shape detection sensor Ladder, safety rope or safety cage |

||||

Product detail pictures:

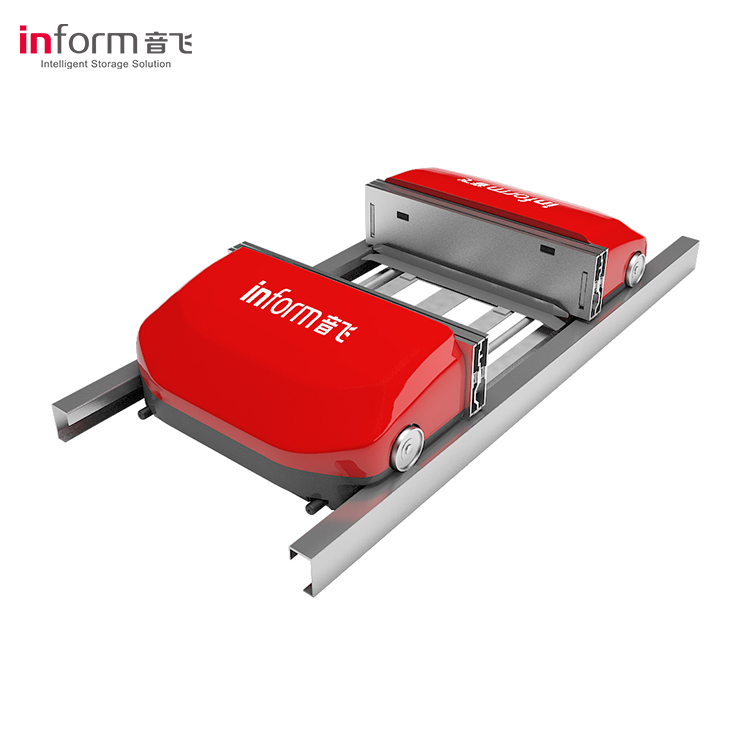

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for High Quality Automated Racking System – Heavy Load Stacker Crane Asrs – INFORM, The product will supply to all over the world, such as: Hamburg , Jamaica , Sierra Leone , Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!

Write your message here and send it to us