1. Customer introduction

Cold storage shuttle and shuttle mover system project in Australia.

2. Project overview

– Pallet size 1165 * 1165 * 1300mm

– 1.2T

– 195 pallets in the four-way shuttle system warehouse

– 5 four-way shuttles

– 1 lifter

– 690 pallets in the shuttle and shuttle mover system warehouse

– 5 sets of shuttle and shuttle movers

– 2 lifters

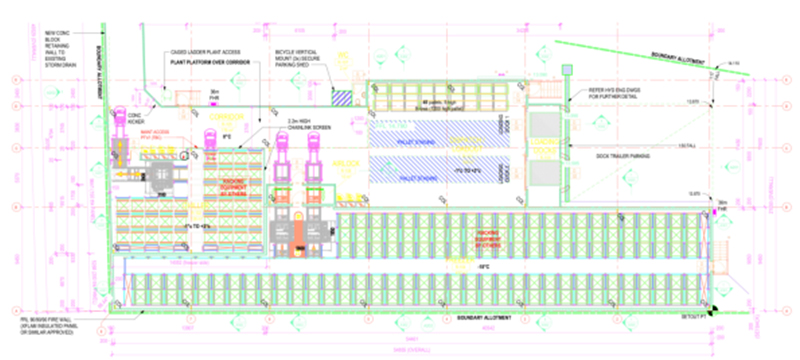

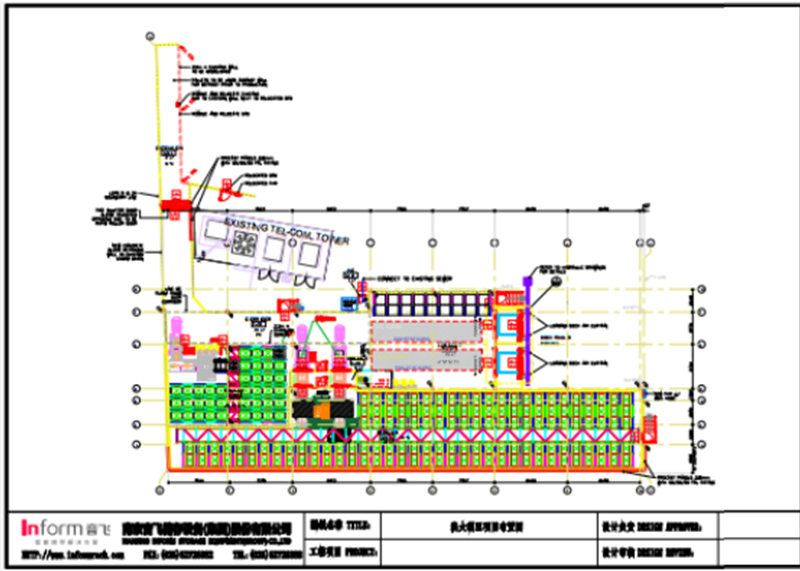

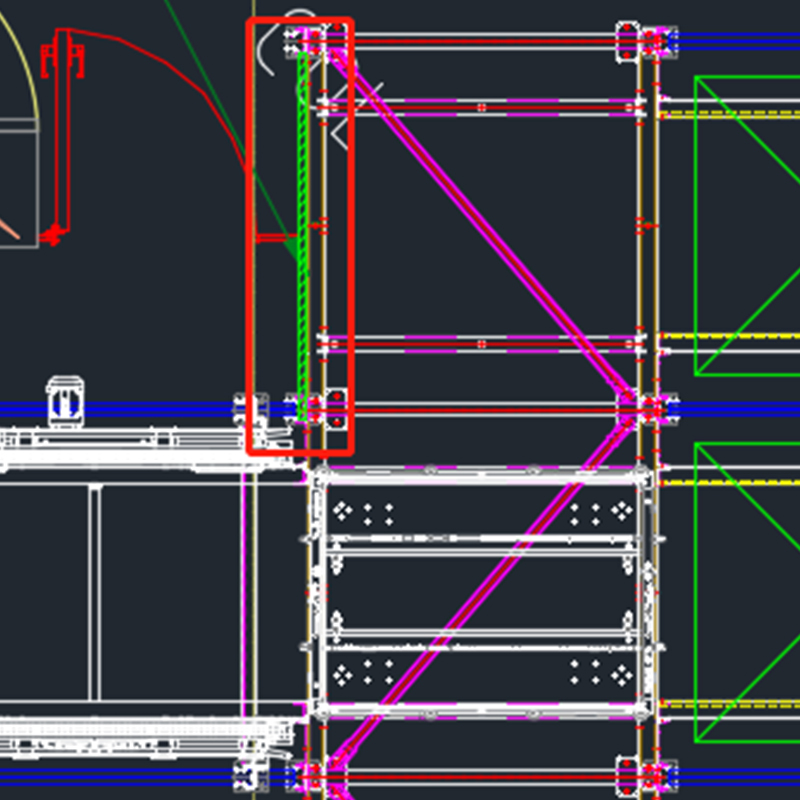

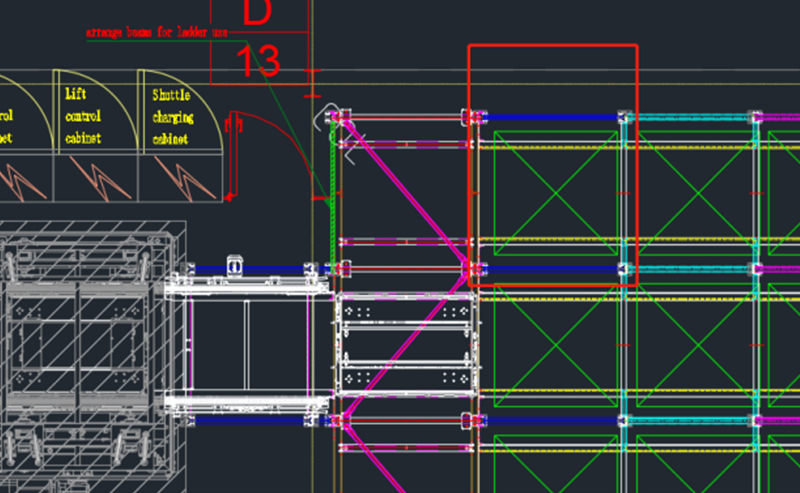

Layout

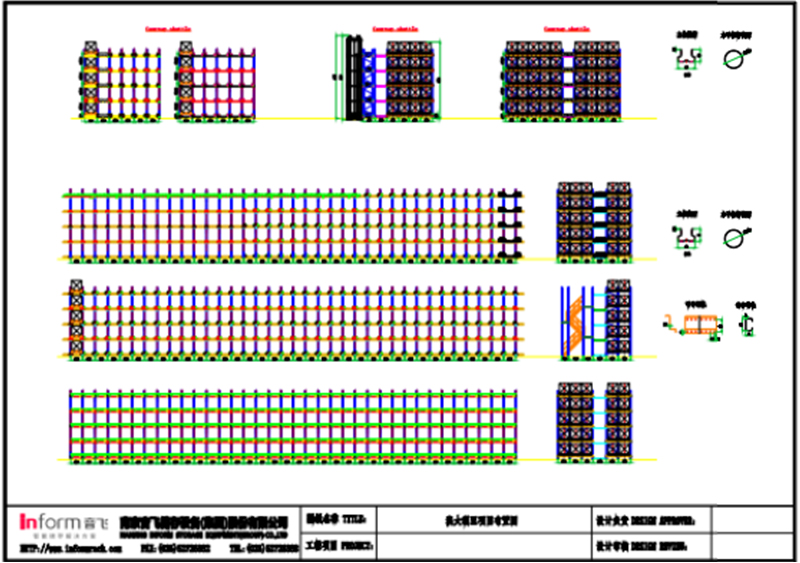

3. Shuttle and shuttle mover system warehouse

- shuttle and shuttle mover system warehouse(690 pallets):

- The level height is 1762.5 mm.

- Frozen warehouse: -18~-20 degrees.

- 5 sets of shuttle and shuttle movers, one per level, without changing levels.

- The second and fourth levels are equipped with maintenance levels.

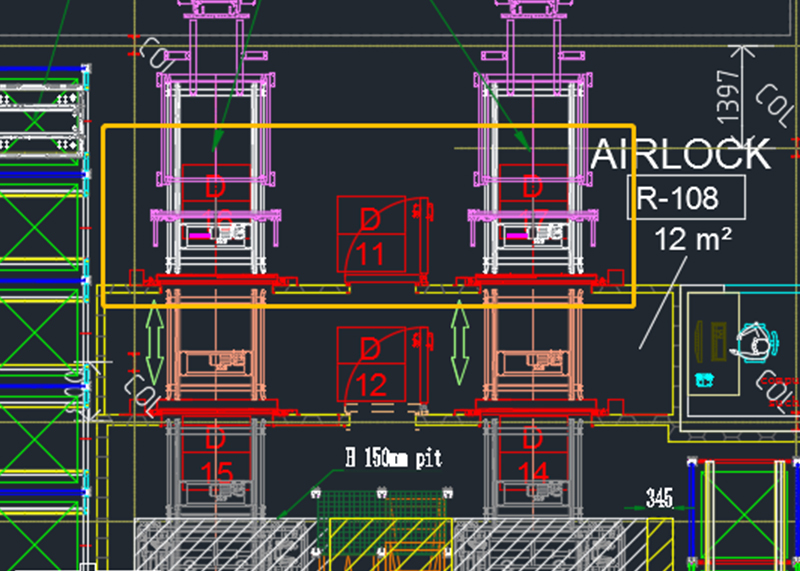

- Equipped with 2 lifters, dig a 150mm deep pit.

- Install movable conveyor lines in the hall.

- A small attic has been set up for maintenance.

- Efficiency: Out+In, 30 pallets per hour.

Add a grating system to prevent personnel from entering by mistake. If someone passes, the system will be powered off. An independent safety PLC is required.

4.Four-way shuttle system warehouse

- Four-way shuttle system warehouse(195 pallets)

- The level height is 1762.5 mm.

- Refrigerated warehouse: -1 to 3 degrees.

- 5 sets of four-way shuttles, one per level, without changing levels.

- The second and fourth levels are equipped with maintenance levels.

- Equipped with 1 lifter to dig a 150mm deep pit.

- Two way conveyor line.

A beam needs to be added here as a ladder.

Forklifts should be able to directly pick up the goods here. Do not consider efficiency issues in this area.

5. System advantages

1) Intelligent scheduling, no need for personnel to operate equipment;

2) It can be connected to a shuttle, and can also handle and transport pallets;

3) 24-hour automatic unmanned batch operation;

4) The shuttle can be charged online during operation;

5) One shuttle mover on the same level corresponds to two or more shuttles to work together;

6) Support omnidirectional forklift AGV operation

Project highlights

① Make full use of the workshop space, complete high-density storage, and maximize the cargo spaces;

② The system is highly flexible, and the number of shuttles can be increased or decreased according to customer traffic requirements to maximize efficiency;

③ Support the operation of multiple shuttles on the same level;

④ The shuttle mover is powered by trolley line, and the system is stable; the shuttle is powered by super capacitor, which can realize 24-hour uninterrupted operation.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926 / +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com

Post time: Oct-17-2023