China National Petroleum Corporation Limited (hereinafter referred to as “CNPC”) is an important state-owned backbone enterprise with a revenue of 3.2 trillion yuan in 2022. It is a comprehensive international energy company mainly engaged in oil and gas business, engineering technology services, petroleum engineering construction, petroleum equipment manufacturing, financial services, new energy development, etc. It is one of the main oil and gas producers and suppliers in China.

Ranked 4th on the 2018 Fortune Global 500 list. According to the 2018 Global Energy Companies Top 250 list released by S&P, CNPC ranks 47th. The “the Belt and Road” Top 100 Chinese Enterprises ranked No. 3. In December 2019, CNPC was selected as the Model 100 brand at the 2019 China Brand Power Ceremony. On May 13, 2020, CNPC ranked 32nd on the 2020 Forbes Global Enterprise 2000 list. On September 28, 2020, it was selected as one of the top 500 Chinese enterprises in 2020, ranking third.

As a global leader in the energy sector, CNPC has always maintained a passion and pursuit for technological innovation. In recent years, the polyolefin packaging warehouse project of Guangdong Petrochemical has become a shining business card of CNPC.

As one of the main domestic oil and gas producers and suppliers, Guangdong Petrochemical has a large number of raw materials and products entering and leaving the factory in a complex manner, including sea transportation, road transportation, railway transportation, flat warehouse, automated warehouse, pipeline transportation, etc. In order to improve logistics efficiency and accuracy, and reduce costs, Guangdong Petrochemical has decided to introduce advanced automated logistics systems.

– AS/RS

– 32 sets of bull track tunnel stacker crane systems

– Approximately 100000 tons of goods

– High reliability and strong load capacity

– A load capacity of up to 15000kg

The project is fully responsible for the AS/RS and related supporting systems of the warehouse by the well-known integrator Today International. With rich experience in warehousing automation, ROBOTECH has become the core equipment provider of the project. According to the characteristics and storage capacity of the goods, 32 sets of bull track tunnel stacker crane systems have been configured for the PP, PE-A/B storage warehouses. There are a total of 68860 bins and pallets in the three automated storage areas, which can store approximately 100000 tons of goods. The Bull model has high reliability and strong load capacity, making it an ideal equipment for handling heavy loads, with a load capacity of up to 15000kg.

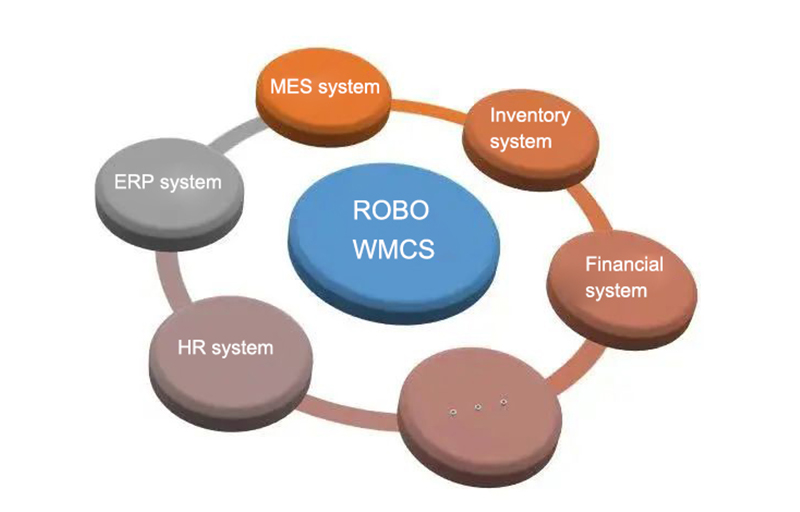

The Guangdong Petrochemical project is the largest and most automated intelligent automated packaging warehouse in the Asian petroleum and petrochemical industry to date. It is the first set of intelligent automated warehouses by CNPC, with intelligent black light operation function. By adopting an advanced WMS intelligent management system, the polyolefin packaging plant and warehouse have achieved intelligent packaging, automatic transportation, intelligent storage management, and automated outbound delivery. This not only greatly improves work efficiency, but also reduces operating costs and labor intensity.

Through the implementation of this project, Guangdong Petrochemical has achieved significant results:

1. Greatly improving the transportation efficiency of incoming and outgoing products and raw materials;

2. The storage and transportation logistics automation system links the sales department’s information system order plan to the Guangdong Petrochemical business department, and the data is automatically stored in the system, simplifying the on-site invoicing process and reducing the workload of data entry;

3. The mobile reservation function allows for real-time viewing of on-site loading progress and vehicle queuing, avoiding the phenomenon of vehicle congestion in the loading area of the refinery;

4. The storage and transportation logistics automation system is integrated with the access control system, oil loading centralized control system, and automated warehouse system to achieve the linkage of license plate recognition and access control permissions, automatic collection and transmission of shipping data, and efficient collaborative management of upstream and downstream business in the supply chain.

ROBOTECH, with its outstanding technology and rich experience, has provided top-notch automated warehouse solutions for Guangdong Petrochemical projects. The successful implementation of this project is of great significance to CNPC, as it is a major measure to promote the transformation and upgrading of refining and new material development. It not only optimizes the industrial layout of refining and chemical business, but also achieves the optimization of device structure and product structure. It also has important driving and practical significance for achieving oil reduction and chemical increase, oil reduction and specialty increase, and will also set a new benchmark for the entire petroleum and petrochemical industry, Showcasing the enormous potential of intelligent warehouse solutions in driving industry development.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926 / +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com

Post time: Oct-11-2023