As the global logistics landscape navigates a period of profound technological transition, the demand for high-density, automated infrastructure has moved from the periphery to the core of supply chain strategy. Addressing this critical need, Inform Storage Equipment (Group) Co., Ltd. (Inform) has unveiled its latest strategic enhancements led by the High-Efficiency Miniload Automated Storage System (AS/RS) Manufacturer. This sophisticated system is specifically engineered to facilitate the rapid handling of small-to-medium loads, including bins, totes, and specialized trays. By integrating high-precision stacker cranes with intelligent management software, the Miniload AS/RS optimizes vertical warehouse volume and ensures high-velocity access to inventory. This technology is particularly vital for modern distribution centers requiring massive SKU management and error-free fulfillment, providing a scalable framework for industries ranging from high-tech electronics to essential retail.

The Global Trajectory of Intelligent Warehousing and Strategic Trends

The evolution of the warehousing industry is currently defined by a movement toward “smart” infrastructure. This transition is not merely a response to local challenges but a global structural shift. Several macroeconomic factors are driving this transformation. First, the escalating cost and diminishing availability of industrial land near major consumer hubs have forced a radical rethink of warehouse design. Enterprises are no longer expanding their physical footprints horizontally; instead, they are looking upward. The adoption of high-bay vertical storage is essential for maintaining proximity to urban markets while keeping operational overhead manageable.

Second, the global labor market is experiencing long-term structural changes. The persistent shortage of skilled logistics personnel, combined with rising wage floors, has made automation a prerequisite for business resilience. Automated systems provide a level of reliability and 24/7 operational capability that human-centric models cannot sustain, particularly in high-intensity environments. Furthermore, the modern workforce is increasingly prioritized for high-level analytical roles, while robotic systems take over repetitive, strenuous, or hazardous tasks, thereby improving overall workplace ergonomics and safety.

Third, the emergence of the Industrial Internet of Things (IIoT) and Big Data analytics has turned the warehouse from a static storage space into a dynamic data node. Real-time tracking, predictive maintenance, and seamless integration with Enterprise Resource Planning (ERP) systems allow for a level of supply chain transparency that was previously impossible. This data-driven approach minimizes inventory “dead stock” and ensures that throughput is perfectly synchronized with market demand.

Finally, environmental sustainability has become a core pillar of corporate governance. Global enterprises are now mandated to reduce the energy intensity of their operations. Automated storage systems contribute significantly to this goal; they can operate in unlit environments to conserve electricity, utilize regenerative energy braking technologies, and follow mathematically optimized movement paths that reduce mechanical friction. These trends represent a permanent shift in how goods are stored and moved across the globe, and Inform’s technology is designed to be the foundation of this new era.

R&D Excellence and Intellectual Property Core

The capacity to lead in the automation sector is fundamentally tied to research and development (R&D) prowess and the protection of intellectual property. Inform has built a formidable technological moat, supported by an extensive portfolio of proprietary innovations. The company’s commitment to technical excellence is evidenced by its 245 valid authorized patents, which include 45 invention patents and 71 utility model patents. Furthermore, the digital intelligence of these systems is secured by 128 software copyright patents, ensuring that the control logic and warehouse management systems are both robust and proprietary.

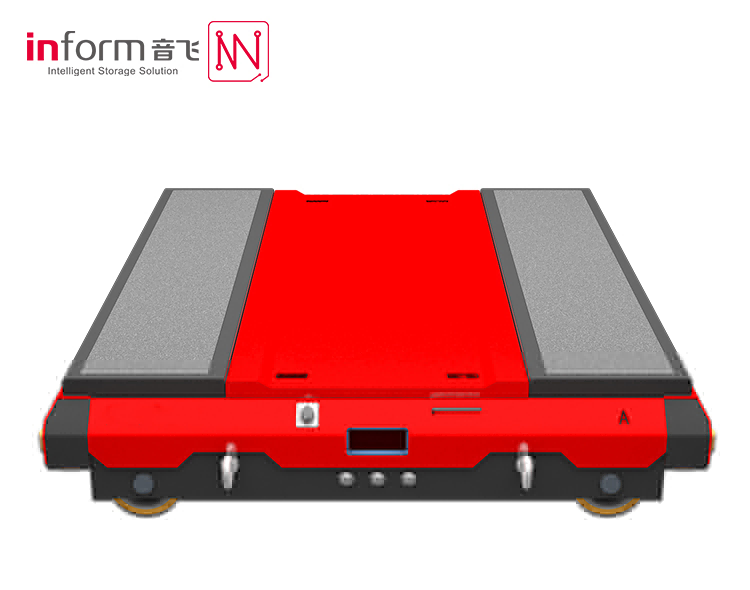

To ensure global compatibility and safety, Inform’s products have achieved the CE certification, a critical benchmark for equipment being deployed in international markets. This rigorous adherence to international standards ensures that every installation meets the highest safety and quality requirements. A primary example of this technical leadership is the Top Fully Automatic And High-Density Pallet Shuttle System From China. By utilizing independent, radio-controlled shuttles that navigate within high-precision racking channels, this system maximizes storage density for heavy palletized goods. It is particularly effective in high-throughput sectors like food and beverage or cold chain logistics, where space efficiency and reliable automation are directly linked to operational profitability.

The reliability of these robotic movements is further guaranteed by the physical infrastructure. Inform provides the China Best Heavy Duty Pallet Racking With Stable Structure, which serves as the indispensable backbone for all automated operations. Designed to withstand the high-frequency dynamic loads of fast-moving cranes and shuttles, this racking system ensures that the automation operates within the strict millimeter tolerances required for peak efficiency. By controlling the quality of both the hardware “skeleton” and the software “brain,” Inform delivers a unified solution that minimizes integration risks for the end user.

Versatile Application Scenarios and Industry Impact

Inform’s technology is deployed in a wide array of high-stakes environments, each requiring unique configurations of automation:

Pharmaceuticals and Healthcare: In an industry where accuracy is life-critical, the Miniload AS/RS provides 100% inventory accuracy and strict batch control. These systems ensure that sensitive medicines are stored in climate-controlled, secure environments with zero human contact, maintaining absolute purity and traceability.

Electronics and High-Tech Manufacturing: Managing thousands of microscopic components requires the precision that only an automated miniload system can provide. By automating the kitting and retrieval process, manufacturers can maintain “just-in-time” (JIT) production lines, significantly reducing the amount of capital tied up in dormant inventory.

E-commerce and Retail Fulfillment: To meet the consumer expectation of rapid delivery, fulfillment centers utilize the pallet shuttle and conveyor systems to sort and stage thousands of unique SKUs per hour. This automation shortens the window between order placement and shipping, providing a decisive competitive advantage in the retail landscape.

Cold Chain Logistics: Working in sub-zero environments is difficult for human labor but ideal for Inform’s automated shuttle systems. By densifying storage, these systems reduce the total volume of air that needs to be refrigerated, leading to substantial energy savings and a lower carbon footprint for the facility.

The success of these installations is not theoretical. By replacing manual forklift operations with high-density automated systems, clients have reported significant gains in throughput and a drastic reduction in equipment downtime. The precision of the high-grade tracks and the stability of the racking structures allow automated robots to operate with minimal wear and tear, extending the lifecycle of the entire warehouse infrastructure.

Conclusion

As the global supply chain moves toward a future defined by autonomy and intelligence, the role of the modern warehouse is being fundamentally redefined. Inform Storage Equipment (Group) Co., Ltd. is at the forefront of this evolution, providing the technical infrastructure and intellectual property necessary to power the next generation of logistics. By combining the expertise of a High-Efficiency Miniload Automated Storage System (AS/RS) Manufacturer with the patented innovations of the Top Fully Automatic And High-Density Pallet Shuttle System From China and the structural integrity of the China Best Heavy Duty Pallet Racking With Stable Structure, Inform enables businesses to transcend the traditional limits of storage. With a vast portfolio of 245 authorized patents and CE-certified quality, Inform remains a trusted partner for enterprises seeking to turn their logistics operations into a strategic engine of growth.

For more information on these advanced storage solutions and to view the complete range of patented technologies, please visit: https://www.inform-international.com/

Post time: Dec-31-2025