Products

-

Two Way Radio Shuttle System

1. Due to the continuous increase in domestic land costs and labor costs, as well as the huge increase in e-commerce’s massive product regulations and order requirements for warehouse efficiency, two-way radio shuttle system has attracted more attention of enterprises, its application becomes more and more extensive, and the market scale is bigger and bigger

2. Two-way radio shuttle system is a major innovation in logistics equipment technology, and its core equipment is radio shuttle. With the gradual solution of key technologies such as batteries, communications, and networks, two-way radio shuttle system has been quickly applied to logistics systems. As a unique automated logistics system, it mainly solves the problems of dense storage and fast access.

-

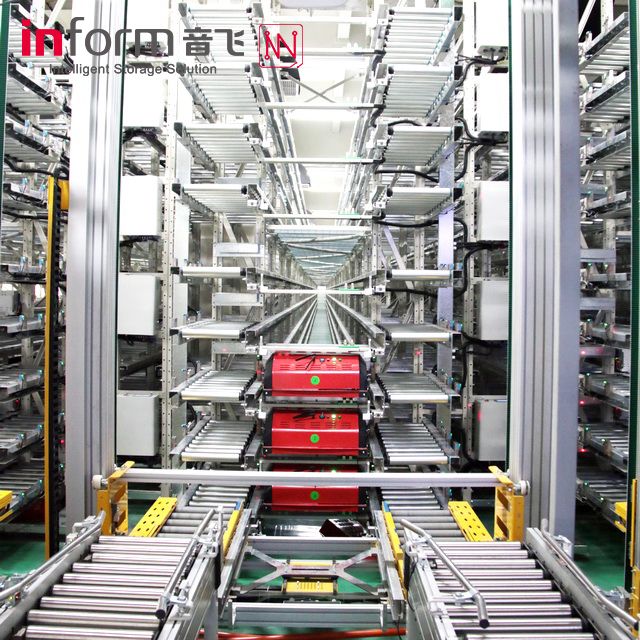

Two Way Multi Shuttle System

The efficient and flexible combination of “two way multi shuttle + fast elevator + goods-to-person picking workstation” meets the requirements of customers for different inbound and outbound frequency. Equipped with WMS and WCS software independently developed by INFORM, it effectively optimizes the order picking sequence, and dispatches various automated equipment to achieve rapid warehousing, and can pick up to 1,000 goods per person per hour.

-

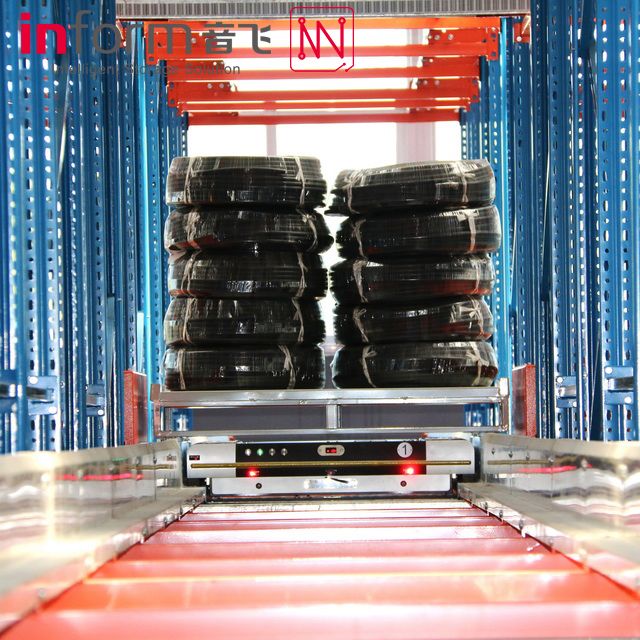

Four Way Radio Shuttle System

Four way radio shuttle system: a complete level of cargo location management (WMS) and equipment dispatching capability (WCS) can ensure the stable and efficient operation of the overall system. In order to avoid waiting for the operation of radio shuttle and elevator, a buffer conveyor line is designed between elevator and rack. Radio shuttle and elevator both transfer the pallets to the buffer conveyor line for transfer operations, thereby improving efficiency.

-

Shuttle Mover System

In recent years, shuttle mover system has developed into a flexible, easy-to-use, energy-saving and environmentally-friendly new delivery equipment in logistics industry. Through the organic combination and reasonable application of shuttle mover + radio shuttle with dense warehouses, It can better adapt to the development and changing needs of enterprises.

-

Miniload ASRS System

Miniload stacker is mainly used in AS/RS warehouse. The storage units are usually as bins, with high dynamic values, advanced and energy-saving drive technology, which enables the customer’s small parts warehouse to achieve higher flexibility.

-

ASRS+Radio Shuttle System

AS/RS + Radio shuttle system is suitable for machinery, metallurgy, chemical, aerospace, electronics, medicine, food processing, tobacco, printing, auto parts, etc, also suitable for distribution centers, large-scale logistics supply chains, airports, ports, also military material warehouses, and training rooms for logistics professionals in colleges and universities.

-

Attic Shuttle

1. Attic Shuttle System is a kind of fully-automated storage solution for bins and cartons. It could store goods quickly and accurately, occupying less storage space, requiring less space and is in more flexible style.

2. Attic shuttle, equipped with a up-and-down moveable and retractable fork, moves along the racking to realize loading and unloading at different levels.

3. The working efficiency of Attic Shuttle System is not higher than Multi Shuttle system. So it’s more suitable for the warehouse requiring not so high efficiency, in order to save cost for the users.

-

New Energy Racking

New energy racking,which is used for static storage of battery cells in the battery cell production line of battery factories, and the storage period is generally not more than 24 hours.

Vehicle: bin. The weight is generally less than 200kg.

-

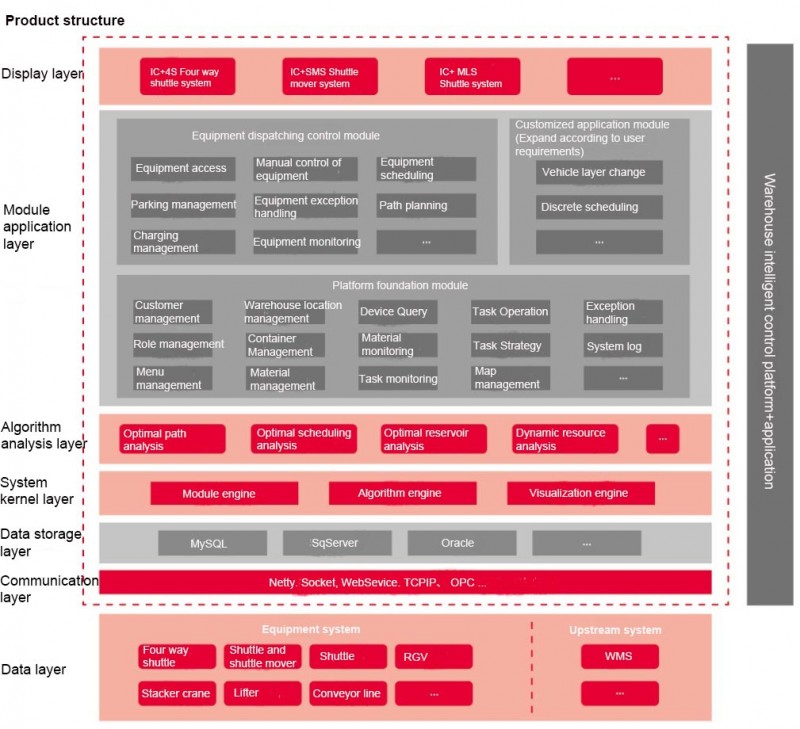

WCS(Warehouse Control System)

WCS is a storage equipment scheduling and control system between WMS system and equipment electromechanical control.

-

Mini Load Stacker Crane for Box

1. The Zebra series stacker crane is medium-sized equipment with a height of up to 20 meters.

The series looks light and thin, but is actually strong and solid, with a lifting speed of up to 180 m/min.2. The advanced design and high-quality structure make Cheetah series stacker crane travel up to 360 m/min. Pallet weight up to 300 kg.

-

Lion Series Stacker Crane

1. The Lion series stacker crane is designed as a sturdy single column up to a height of 25 meters. The travel speed can reach 200 m/min and the load can reach 1500 kg.

2. The solution is widely used in different applications, and ROBOTECH has rich experience in the industries, like: 3C Electronics, Pharmaceuticals, Automobile, Food & Beverage, Manufacturing, Cold-chain, New Energy, Tobacco and etc.

-

Giraffe Series Stacker Crane

1. The Giraffe series stacker crane is designed with double uprights. Installation height up to 35 meters. Pallet weights up to 1500 kg.

2.The solution is widely used in different applications, and ROBOTECH has rich experience in the industries, like: 3C Electronics, Pharmaceuticals, Automobile, Food & Beverage, Manufacturing, Cold-chain, New Energy, Tobacco and etc.