ASRS Racking

Racking Components

Product Analysis

| Racking type: | AS/RS (Automated Storage and Retrieval System) | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 1000-3000kg/pallet |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 75mm | Place of origin | Nanjing, China |

| Application: | industrial production, logistics, commodity manufacturing , military applications industries | ||

① High space Utilization

The space utilization of AS/RS is 2-5 times than common storage. The racking can be designed as single-depth or double-depth to improve storage capacity, also compatible with any size pallet.

② Improving efficiency of storage and picking

AS/RS is dynamic storage and advanced logistics system, improving production management level. Compared with static racking system, the storage and picking efficiency is much improved.

③ Labor-saving operation

The pallet moving is handled by equipment, and controlled by software system. So it requires minimum labor and allows to operate unattended around the clock.

④Mini Load AS/RS

In addition to regular pallet storage, there is the other AS/RS racking type, suitable for carton/box/bin storage, called Mini Load AS/RS. Similar as AS/RS, mini load is a combination of shelving, equipments and software system.

⑤ High adaptability with other automated storage robots

AS/RS is able to work with other automated storage robots, like shuttle car, shuttle mover, four way shuttle and so on, to meet diversified storage requirement and increase efficiency.

Project cases

Industry: Paper / Pallet Positions: around 60,000 / Height: 24m

Industry: Soy Sauce Pallet Positions: around 31,000 Height: 32m

Industry: Soy Sauce Pallet Positions: around 31,000 Height: 32m

Industry: Industry: Ceramics Pallet Positions: around 52,000 Height: 26m

Industry: Industry: Ceramics Pallet Positions: around 52,000 Height: 26m

Miniload ASRS racking

Industry: Garments

Carton Positions: 30,000

Height: 9m

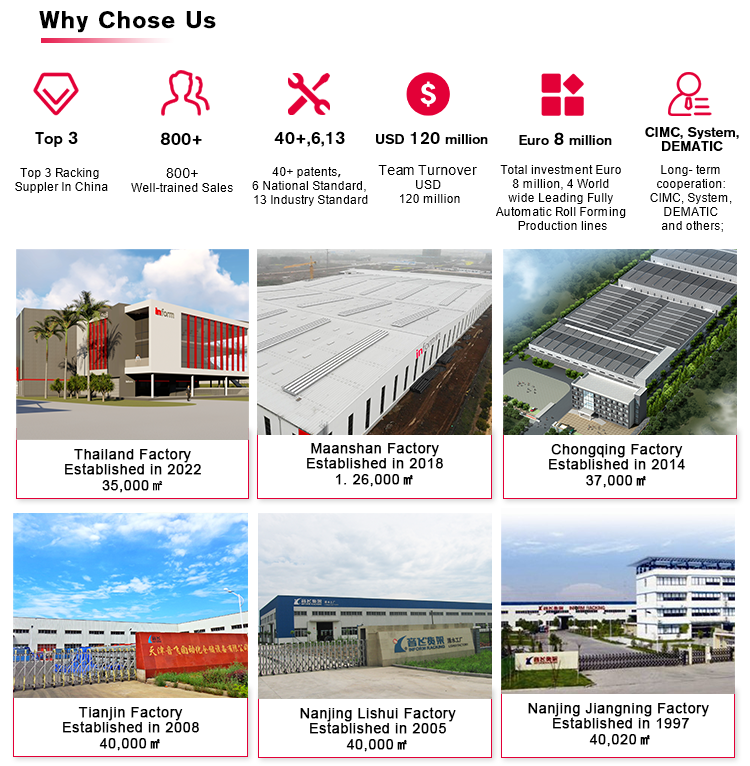

Why Choose Us

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed enterprise, specialized in the logistic storage solution field since 1997( 27 years of experience).

2. Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3. Inform owns 6 factories, with over 1500 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.