1. Project Background and Requirements

A well-known auto company cooperated by Nanjing Inform Storage Group this time is an active practitioner of smart logistics in the auto parts industry. After various considerations, the four-way multi shuttle solution provided by Nanjing Inform Storage Group can better meet the current business needs. Adapted to the company's development and subsequent business extension, and assisted its order response timeliness. While improving the efficiency of the enterprise, it effectively saves the demand for manpower and operating costs, and has achieved remarkable results.

For 3PL enterprises of auto parts, it also brings great difficulties to the warehouse management of production enterprises, mainly reflected in:

- SKU continues to increase, and it is difficult to plan and manage cargo space.

Conventional auto parts warehouses are mostly divided into pallet warehouses that store large pieces, and light shelves or multi-tier shelving that store small pieces. For the storage of small items, due to the increasing number of SKUs, long-tail SKUs cannot be removed from the shelves, and the planning and optimization management of the storage space is relatively heavy. - Low utilization rate of warehouse storage capacity

For the standard warehouse, there is a headroom of more than 9 meters. Except for the three-story attic, other light shelves have the problem that the upper space cannot be fully utilized, and the rent per unit area is wasted. - The storage area is large and there are many handling workers

The warehouse area is too large, and the running distance of employees is too long, resulting in low efficiency of single-person operation, so that more workers such as replenishment, picking, inventory, and warehouse transfer are required. - The workload of picking out the warehouse is large and error-prone

Most of the manual operation warehouses adopt the method of picking and broadcasting at the same time, and lack of fool-proof means. There are often problems such as employees missing scanning codes, putting in the wrong box, and sending more or less hair. Later review and packaging need to invest more manpower. - Increasing demand for information

With the advent of the Internet of Things era, auto parts need more intelligent information means to manage inventory information.

2. Project overview and main process

The project covers an area of about 2,000 square meters, with a height of nearly 10 meters of automated intensive storage warehouses and a total of nearly 20,000 cargo spaces. The turnover box can be divided into two compartments, three compartments and four compartments, and can store up to nearly 70,000 SKUs. This project is equipped with 15 four-way multi shuttles, 3 bin elevators, 1 set of rack end conveyor line and box-type warehouse front conveyor module, and 3 sets of goods-to-person picking tables.

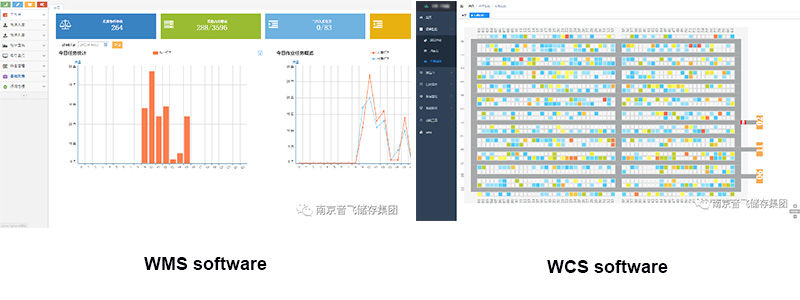

The system configures the WMS software to connect to the enterprise's ERP system, configures the WCS software, and is responsible for the decomposition, distribution and equipment scheduling management of job tasks.

The in-out process of finished products is as follows:

1) . Inbound

- The WMS system manages the binding of turnover box barcodes and materials, laying the foundation for inventory management;

- Manually complete the online work of the turnover box, and the turnover box will enter the conveying system after code scanning and ultra-high detection without abnormality;

- The turnover box entering the conveying system, according to the system distribution logic, is transferred to the designated cargo space through the box elevator and the four-way multi shuttle.

- After WMS receives the instruction to complete the delivery of the four-way multi shuttle, it will update the inventory information and the warehousing work will be completed.

2) . Storage

The materials that need to be stored are divided into three categories of ABC according to the previous big data judgment, and the system cargo space planning is also designed according to the ABC. The cargo space directly facing the sub-channel of the box elevator on each floor is defined as the Class A material storage area, the surrounding area is the Class B material storage area, and the other areas are the Class C material storage area.

3) . Pick

- After the system receives the ERP order, it will automatically generate the picking wave, calculate the required materials, and generate the material turnover box outbound task according to the storage unit where the material is located;

- The material turnover box is transferred to the picking station after passing through the four-way multi shuttle, bin elevator and conveying line;

- A picking station has multiple material turnover boxes for operators to pick in turn, and operators do not have to wait for turnover boxes;

- Equipped with a WMS software client display screen, which prompts the information of the grid where the material is located, material information, etc. At the same time, the light on the top of the picking table illuminates the grid to be picked to remind the operator, thereby improving the operator's picking efficiency;

- Equipped with multiple order boxes, there are button lights on the corresponding positions, reminding operators to put materials into the lighted order boxes to prevent fools and reduce errors.

4) . Order box outbound

After the order box is picked, the system automatically transfers it to the warehouse port conveyor line. After scanning the bar code of the turnover box through the PDA, the system automatically prints the packing list and order information to provide the basis for subsequent collection, box closing and review. After the small order material is combined with other large order materials, it will be shipped to the customer in time.

3. Project difficulties and core highlights

This project overcomes many technical difficulties in the design process, such as:

- There are many material SKUs that customers need to store on site.

- Due to the mixing of materials, it will increase the time for personnel to judge the goods, and the error rate of personnel judgment will increase.

- With the increase of business volume, the efficiency of inbound and outbound storage can be flexibly improved, and the transition will be smooth.

Through continuous efforts to overcome difficulties, the project was successfully implemented, and there were many highlights in the implementation process:

- Conveyor line size loop system design

- Multifunctional Picking Table Design

- Mature software system escort

- Configure a real-time monitoring system to help customers keep abreast of operational information and critical warnings

• Help companies save costs

• Safe operation

• Increased throughput

• Informatization construction has been improved

• Flexible, modular and expandable

Smart logistics is an integrated scenario application of automation and intelligent technology. It empowers each link, effectively achieves a substantial increase in storage space capacity, and quickly and accurately implements parts inbound, outbound, sorting, information processing and other operations. Through the analysis of monitoring operation data, we can accurately grasp the business pain points, continuously optimize business capabilities, and reduce costs and increase efficiency. The technology application and big data analysis based on smart logistics will become the main direction of the development of parts logistics, as an important indicator to measure the level of enterprise logistics operation and management.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: kevin@informrack.com

Post time: Sep-29-2022